Digital supply chain twins, explained

Digital twin technology is changing the shape of all sorts of industries. Aerospace and defense. Automotive. Formula One racing. Even underwater archaeology, as was shown with the Titanic digital twin that enabled researchers to digitally re-create the shipwreck with an unprecedented degree of detail earlier this year. And, of course, digital twins are transforming pharmaceutical and healthcare supply chains, the consumer packaged goods industry and industrial manufacturing, in which Bluecrux is a proven expert.

What is a digital supply chain twin?

Essentially, a digital twin is a virtual representation of a physical object or process that captures both physical and behavioral characteristics. According to our partners over at Gartner, a digital supply chain twin (DSCT) is “a digital representation of the end-to-end physical supply chain that can be used to drive understanding and make decisions.’’ In other words, a technology that provides an unprecedented degree of detail about your supply chain.

With a DSCT, you can have one single highly detailed end-to-end supply chain data model that offers visibility on everything from sourcing through to delivery. It represents the logistics network and information flows within your supply chain. There are digital supply chain twins available for warehouses, suppliers, management, tracking fulfilment—the list goes on.

What are the main benefits of a digital supply chain twin?

A digital supply chain twin, first and foremost:

- Provides you with a better grasp of your supply chain.

- Enables you to react and improve where needed, while showing you where you’re on the right track.

- Gives you full end-to-end visibility of your value chain operations and intelligent insights based on the most up-to-date information.

What’s more, by capturing your demonstrated performance and factoring end-to-end variability into the equation, a digital supply chain twin:

- Fuels understanding to facilitate design, policy and process improvements, as well as conformance and compliance.

- Enables better decision-making through early alerting when significant changes might be occurring and predict the consequences of these changes.

- Estimates the likelihood that a plan will produce the intended results.

As Gartner suggests, a digital supply chain twin will allow you to “move from unknown uncertainty to known variability,” and to include that variability in your decision-making through probabilistic planning.

Implementing a digital supply chain twin

As with implementing any new technology for your supply chain, launching a digital supply chain twin can feel like a daunting process. Here are the most common questions organizations ask:

- How much time and energy and manpower will need to be devoted to this kind of project?

- Should we try building a digital twin in-house or rather invest in a SaaS solution that could take on the majority of the legwork?

The bottom line, however, is that a best-of-breed digital supply chain twin can be a game-changer for an organization, ushering in the agility necessary to navigate the unpredictable terrains of today’s VUCA landscape.

3 success factors for a DSCT

- For a digital twin to function effectively, it must integrate numerous business processes. In a global supply chain operation, this means gathering data from various facilities and branches, potentially scattered across the globe. This data may span different business areas, such as sales, finance, logistics, production and procurement. Given that these sectors might operate on different systems, this results in a mixed IT environment. Nonetheless, collaboration across these diverse platforms is essential for successful digital twin implementation.

2. Relying solely on master data isn’t enough for creating or maintaining a digital twin. The purpose of the twin is to simulate, and for that, you need more than just entities, locations and their attributes. It’s essential to also capture the interactions between these elements, which can be achieved via transactions. When building a digital supply chain twin, it’s helpful to examine all the generated transactions, like purchase orders, shipment requests, goods issued requests and so forth. Mapping these transactions can be challenging, especially when sourced from multiple systems, but it’s crucial. This depth of data provides insights, such as average production times and their variations.

3. A digital supply chain twin should be adaptable to evolving supply chain dynamics. Supply chain structures and dynamics are always in flux. Factors like new product introductions, macroeconomic shifts and company mergers can all influence the supply chain. It’s vital to design a digital twin that’s adaptable to these changes. Moreover, various processes occur at different paces—some take mere minutes, while others span months. Your digital twin must be equipped to handle this diversity in timing.

To build or not to build

When considering the implementation of a digital supply chain twin, businesses face the choice of building in-house or opting for third-party solutions. Building a digital twin in-house offers the freedom of customization and to create a solution that will closely align with a business’ setup, processes and organization while leveraging a company’s internal knowledge. However, this tailored approach has its drawbacks. Development can be both expensive and time-consuming. Moreover, not all companies have IT as their core strength, making the endeavor even more challenging.

On the other hand, outsourcing offers the efficiency of SaaS solutions. These ready-made solutions can be swiftly deployed, negating the need for a hefty upfront investment. SaaS platforms provide flexibility, allowing businesses to “test the waters” before committing fully. Additionally, vendors specialize exclusively in digital twin technology, assuring businesses of the quality and ongoing development of the product. One of the main attractions of SaaS solutions is the reduced overhead. Businesses using these platforms don’t have to bear the brunt of managing the infrastructure or invest significantly in IT.

Though the benefits are undeniable—from enhanced analytics and risk management to the potential for sophisticated simulations to optimize the supply chain—it’s true that digital supply chain twins don’t come cheaply. A closer look at the costs reveals a notable difference between the two options aforementioned. For global supply chains looking to represent vast networks with millions of transactions, the investment in an in-house solution can be monumental, with development potentially incurring millions initially and high annual maintenance costs. SaaS platforms, with their multi-tenant shared infrastructure model, clearly emerge as a more economical alternative.

Digital supply chain twin use cases

Having discussed some of the considerations and intricacies of implementing a digital supply chain twin, let’s now delve into the practical scenarios and benefits that this technology brings to the table. The essence of a DSCT lies not just in its creation but in its application—how it revolutionizes various facets of supply chain management, from its micro-operations to its overarching strategies.

By merging the virtual and physical worlds, a DSCT offers an evolving model that’s more than just a reflection of your supply chain, as it actively updates, learns and responds to real-world changes. As we navigate through the applications of digital supply chain twins, we’ll uncover the tangible benefits that await businesses—from cost reduction and efficiency boosters to resilience builders and sustainability enhancers. Understanding digital supply chain twins’ diverse uses is essential in reaping their full potential. Without further ado, let’s explore some use cases.

Enhance ROI of your planning tech

Let’s say you have an APS system. Maybe you have a data lake. Or even a data warehouse. Is a digital supply chain twin really necessary? The answer is yes.

The vast majority of companies aren’t getting the most out of their advanced planning and scheduling (APS) systems. There are indeed shortcomings in APS solutions, but they can be mitigated with the implementation of a digital supply chain twin, which can enhance the overall ROI of your planning technologies.

Read more:

It’s critical for major international companies with complex supply chains to be able to effectively track, collate and manage data in today’s connected world. This needs to happen across all the steps in the end-to-end product flow to see the bigger picture and mitigate supply chain threats as they emerge.

At too many of these companies, internal and external stakeholders are using multiple informatics platforms, and thus, the data is scattered across a range of different systems. Implementing a data lake for centralized consolidation is but one part of the data jigsaw puzzle. What’s needed to trace supply chain flows in an end-to-end way is a digital supply chain twin, which connects data automatically and provides a single source of truth.

Read more:

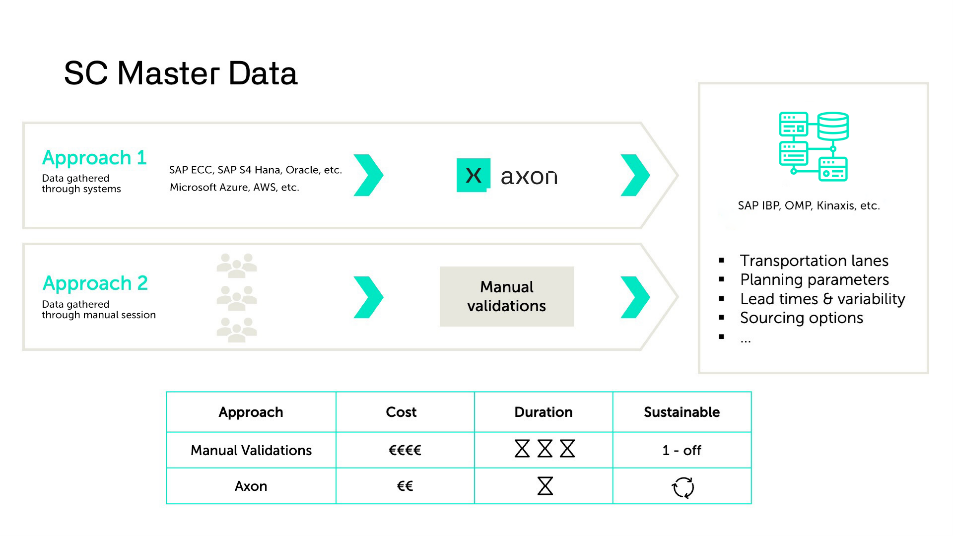

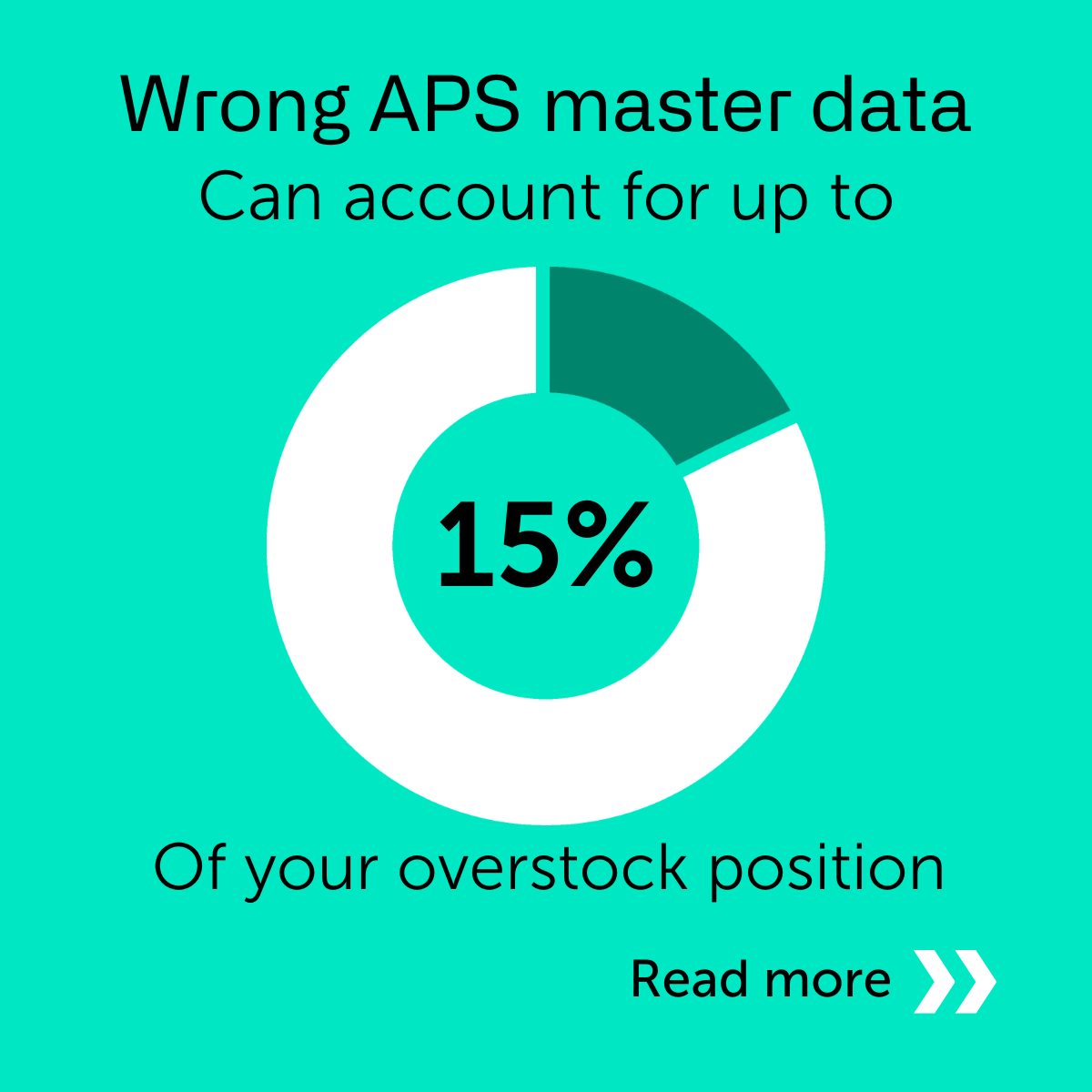

Master data

If you’re running a supply chain technology implementation, you’re likely trying to feed it master data. Gartner actually calls master data one of the most critical success factors of these programs. Incorrect APS master data can become a major factor in your supply chain. If you’re uncertain about the accuracy of your data, you’re not alone. But it doesn’t have to be that way. A digital supply chain twin can reveal the (in)accuracy of your master data and help you make it right.

Read more:

Digital value stream mapping

Value stream mapping is among the keys to strengthening your supply chain operations. It can help you get a better visual of the situation at hand within your operations and plan for a more efficient future that reduces or eliminates waste in your value stream. It can be a challenging task to create value stream mapping visuals, particularly with a manual effort and uncertain numbers. But with a digital supply chain twin, it’s possible—and it’s worth it.

Read more:

Saving time with a digital twin

A data model is fundamental for all digital systems. You need it for your network optimization system. Your planning system. Different control towers, command centers. You name it. Some companies hesitate to implement tech tools like a digital supply chain twin to build a real-time, end-to-end data model, fearing that resource constraints within the team make it a non-starter. But that fear is unfounded. A digital supply chain twin will, in practice, actually save your resources time.

Read more:

Saving money with a digital twin

Finding inventory savings is a top priority for many companies as they strive to secure target service levels. For industries in which service and on-time delivery are vital—like pharma—inventory management is even more essential. Planning and operations excellence, enabled by a digital supply chain twin, can pave the way toward considerable inventory savings.

Read more:

End-to-end visibility for your stakeholders

When data is scattered around several different systems, it’s far more challenging than it needs to be for stakeholders across a company’s supply chain pipeline to do their jobs. Value chain managers, end-to-end planners, operational excellence leads, finance managers and complaint managers, among others, all stand to benefit tremendously from superior end-to-end visibility. A digital supply chain twin can help make life significantly easier for these stakeholders.

Read more:

Process mining

Traditional process mining tools focus on single ERP systems, rather than integrating data across multiple transactional systems—from ERP to MES and WMS. A digital supply chain twin can provide a holistic view that harmonizes scattered data, enabling businesses to associate specific customer orders with their entire supply chain, generating an end-to-end value stream map, optimizing on-time deliveries and evaluating the impact of supply changes.

Read more:

Explainable AI

AI is being integrated into various industries and changing the way we do business. However, mainstream adoption comes with challenges, including building trust in artificial intelligence, as well as understandability. While there are limitations with current models, there are methods to make transparency, interpretability and explainability possible. A digital supply chain twin takes the complexities of AI-driven predictions and simulations and translates them into clear, comprehensible explanations, offering supply chain professionals the confidence to make informed decisions based on AI-driven insights that can be explained.

Read more:

Case studies: Successful implementations of digital supply chain twins

Prescribing dynamic planning master data based on event data

One of the most prominent multinational healthcare companies, which ranks among the Fortune 500, embarked on a substantial planning transformation journey. This leading player in medical devices, pharmaceuticals and consumer packaged goods has a vast reach, operating through approximately 250 subsidiaries across 60 countries, with their products available in over 175 nations. As part of the company’s transformative vision for a unified global organization and seamless planning process, it faced a significant challenge: the lack of end-to-end visibility across its supply chain.

To address this, the company meticulously identified their most “planning-sensitive parameters,” which include aspects like transport lead times, quality release times, capacities and scrap rates. These parameters, pivotal for planning precision, were synchronized with real-world data. With the aid of the cutting-edge analytics enabled by a digital supply chain twin, planning parameters were constantly fine-tuned based on genuine product batch data. These recalibrated parameters were then contrasted with the existing planning master data, leading to exception-based suggestions for modifications. This innovative approach empowered planners with continuously accurate data, reducing the burden of manual adjustments.

The outcomes of this transformation were notable:

- A reduction in end-to-end lead times.

- Marked enhancement in planning efficiency.

- Bolstered visibility and control over the supply chain.

- The company realized a commendable 20 million USD in inventory savings and a swift 3-month payback period for their proof of value.

Providing E2E brand flow visibility by building a digital twin

A leading multinational health care company, which ranks among the Fortune 500 and has a broad presence in the medical devices, pharmaceutical and consumer packaged goods sectors, was keen to introduce improved end-to-end brand flow visibility. With around 250 subsidiaries operating in 60 countries and products available in over 175 countries, their primary challenge was a lack of end-to-end visibility over its extensive supply chain network.

To address this, the company invested in a digital twin for its entire supply chain, spanning from the initial production of active ingredients to the delivery at local distribution centers for all its brands and SKUs. This intricate digital mapping was made possible through advanced crawling algorithms that harmonized and integrated data from multiple ERP systems.

As a result, the company achieved:

- Improved E2E flow visibility, network synchronization and supply chain accuracy and control.

- Frictionless planning.

- A platform from which they can generate further value creation for the company.

The current digital supply chain twin market

At present, the digital supply chain twin market is experiencing considerable growth, driven by the increasing need for organizations to gain real-time visibility and insights into their supply chain operations. As global supply chains become more complex and interconnected, the ability to create a virtual representation of the supply chain—in other words, a digital twin—has become an invaluable tool for organizations seeking to improve decision-making, optimize processes and enhance responsiveness to market changes.

The leading vendors in this space are offering solutions that integrate with different supply chain systems, enabling organizations to create digital twins of their supply chains and gain actionable insights. The market is evolving rapidly, with new players and innovations continuing to emerge, driving further advancements in digital supply chain twin technology.

Who are some of the current DSCT vendors on the market?

- SAP Integrated Business Planning (SAP IBP) is a solution that supports supply chain planning, from demand planning to inventory optimization. Known for its integration with other SAP solutions, it includes capabilities for creating digital twins of supply chains, providing organizations with insights that can help them anticipate and respond to market changes.

- The Pros: Real-time insights, predictive analytics, simulation capabilities, integration with other SAP solutions.

- The Cons: Complexity, limited customization.

- Oracle Supply Chain Planning Cloud, a part of Oracle’s broader suite of supply chain management applications, offers tools for planning, execution and analysis, including features that support the creation of digital supply chain twins. Oracle’s solution is flexible and scalable, catering to the needs of businesses of various sizes.

- The Pros: Real-time visibility and insights, predictive analytics, collaboration and transparency, scalability and agility.

- The Cons: Complexity, limited customization.

- Kinaxis RapidResponse is a supply chain management solution that provides such capabilities as demand planning, inventory management and capacity planning.

- The Pros: Comprehensive capabilities, real-time data and insights, advanced analytics and reporting, scalability and flexibility.

- The Cons: Complexity, limited supplier collaboration features, integration challenges, limited support.

- IBM Sterling Supply Chain Insights with Watson, which leverages AI technology, allows organizations to model different scenarios and predict the impact of changes in their supply chain. IBM Sterling’s platform is known for its innovation and advanced analytics capabilities.

- The Pros: Real-time intelligence, end-to-end visibility, proactive risk management, improved collaboration, reduced supply chain costs.

- The Cons: Complexity, data requirements, in-house skills requirements.

- Celonis is a provider of process mining software that can be used to analyze business processes based on data collected from IT systems. It helps organizations identify inefficiencies, bottlenecks in their processes and where there are opportunities for cost savings or other improvements.

- The Pros: Comprehensive features, AI capabilities, scalability.

- The Cons: Limited support for certain systems and data sources, steep learning curve.

Axon’s DSCT

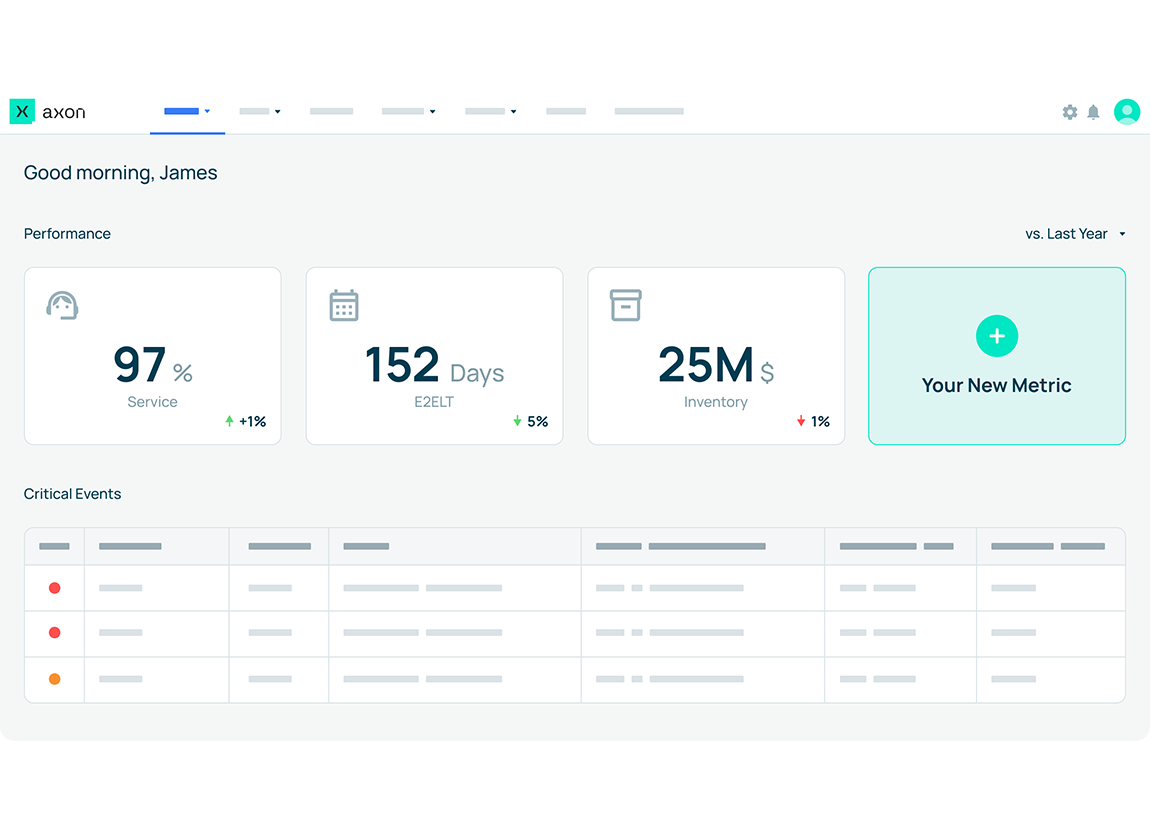

Bluecrux’s Axon distinguishes itself in the digital supply chain twin market by offering a truly comprehensive and integrated solution that leverages artificial intelligence and machine learning to provide real-time insights and predictive analytics. Moreover, its user-friendly interface and tailored dashboards enable organizations to easily visualize and analyze their supply chain operations, facilitating better decision-making.

Axon focuses on collaboration and cross-functional integration. The platform is designed to connect various stakeholders across the supply chain, from suppliers to customers, ensuring that all relevant parties have access to the same information and can collaborate effectively to optimize the supply chain.

Further, Axon’s modular approach allows organizations to customize the platform according to their specific needs and scale the solution as their business grows. With this flexibility—combined with Bluecrux’s industry expertise and dedicated customer support—Axon has you covered.

How exactly does Axon’s technology work?

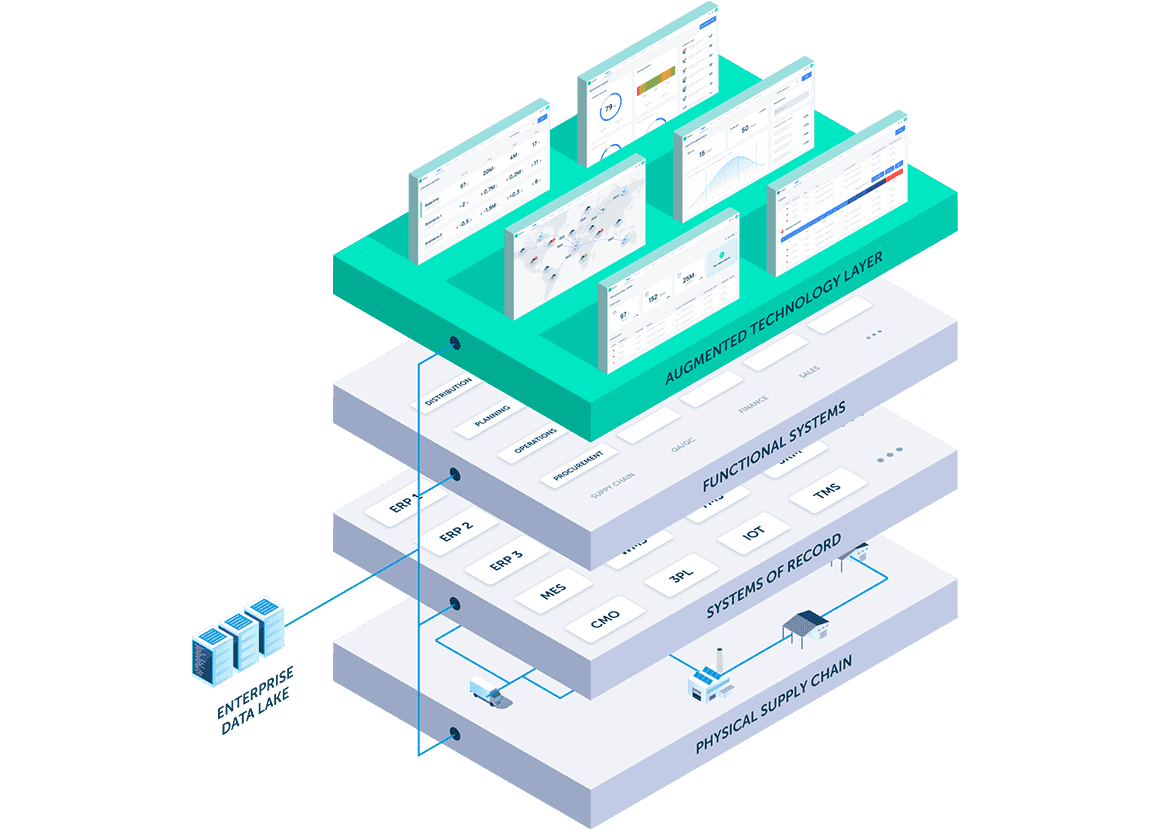

The Axon platform

The first order of business when it comes to building your digital supply chain twin is delving into the data. Axon collates, harmonizes and connects your existing data, which is often scattered across various unconnected systems, to provide a single source of truth. This puts you in a position to take advantage of your data’s real value. With better data, you’ll then have access to accurate and up-to-date insights, which will in turn help you evaluate your operational performance and track how well you’re set up to hit your targets and benchmarks.

Think of this as a three-step process, which goes as follows:

- Critical data is pulled from your data lake or source systems.

- Your data is then harmonized to speak the same language.

- Your data is linked and contextualized to develop true insights.

Axon accomplishes all of this with the help of our proprietary AI algorithms.

Axon add-on solutions

Axon’s digital supply chain twin boasts three solutions that can be added to work in tandem to enhance your supply chain. Our end-to-end visibility solution, Axon Observe can deliver full visibility over every level of your network. Axon Decide is our probabilistic simulation solution, which enables you to put your newfound E2E visibility to work in a fully operational simulation environment. Rounding out the solution trio, our Axon Control supply chain control tower gives you the ability to navigate your supply chain operations via intelligent analysis and insights.

Axon Observe: E2E visibility & performance

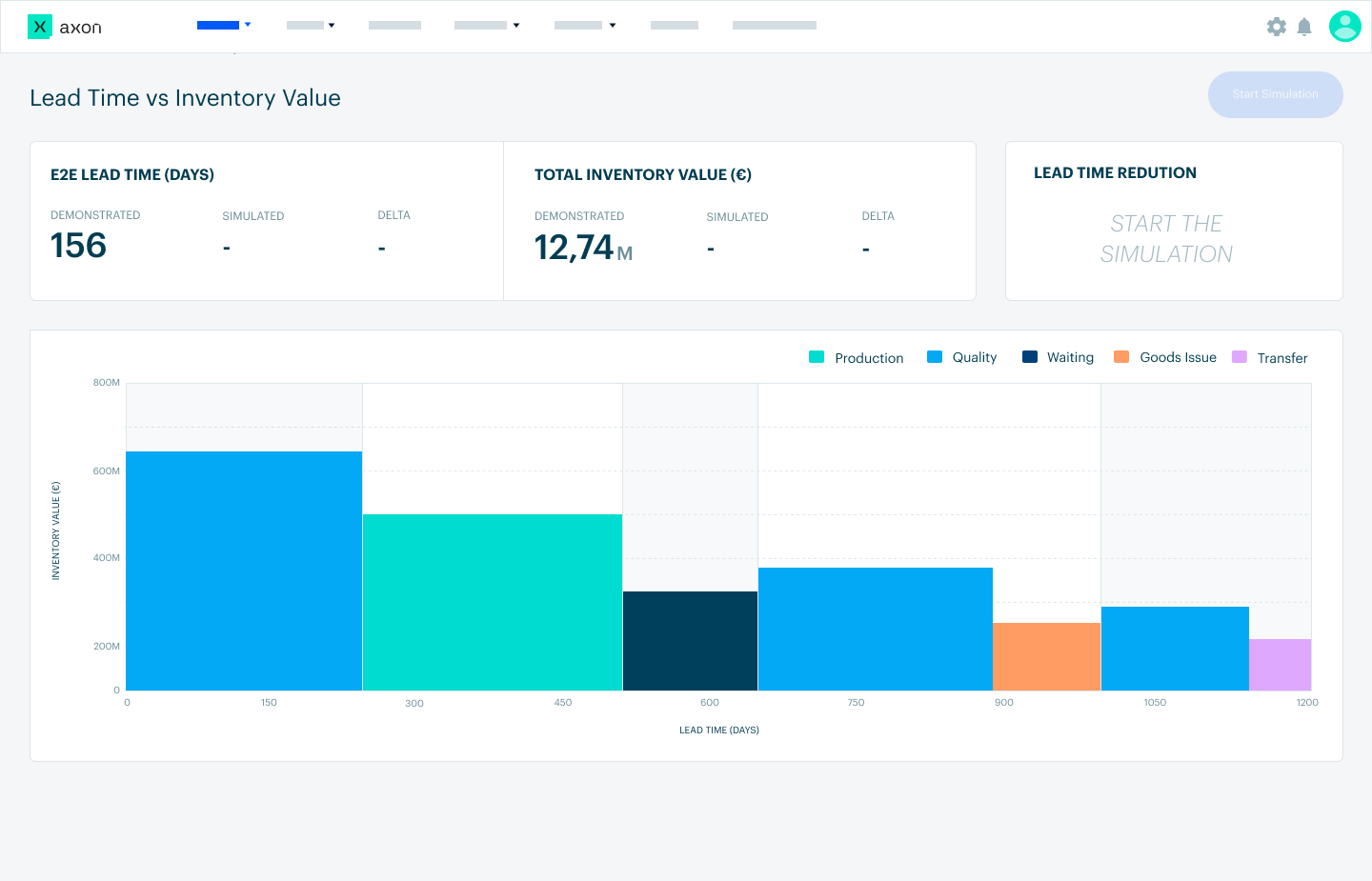

Axon Observe gives you the chance to really understand what’s going on in your complex supply chain. It captures both the breadth and depth of your operations, as it monitors the configuration, performance and observed parameters of your supply chain. Axon Observe can answer questions about detailed E2E product flows, whether or not your planning master data reflects reality, where you can reduce E2E lead time and the degree of variability on your supply chain.

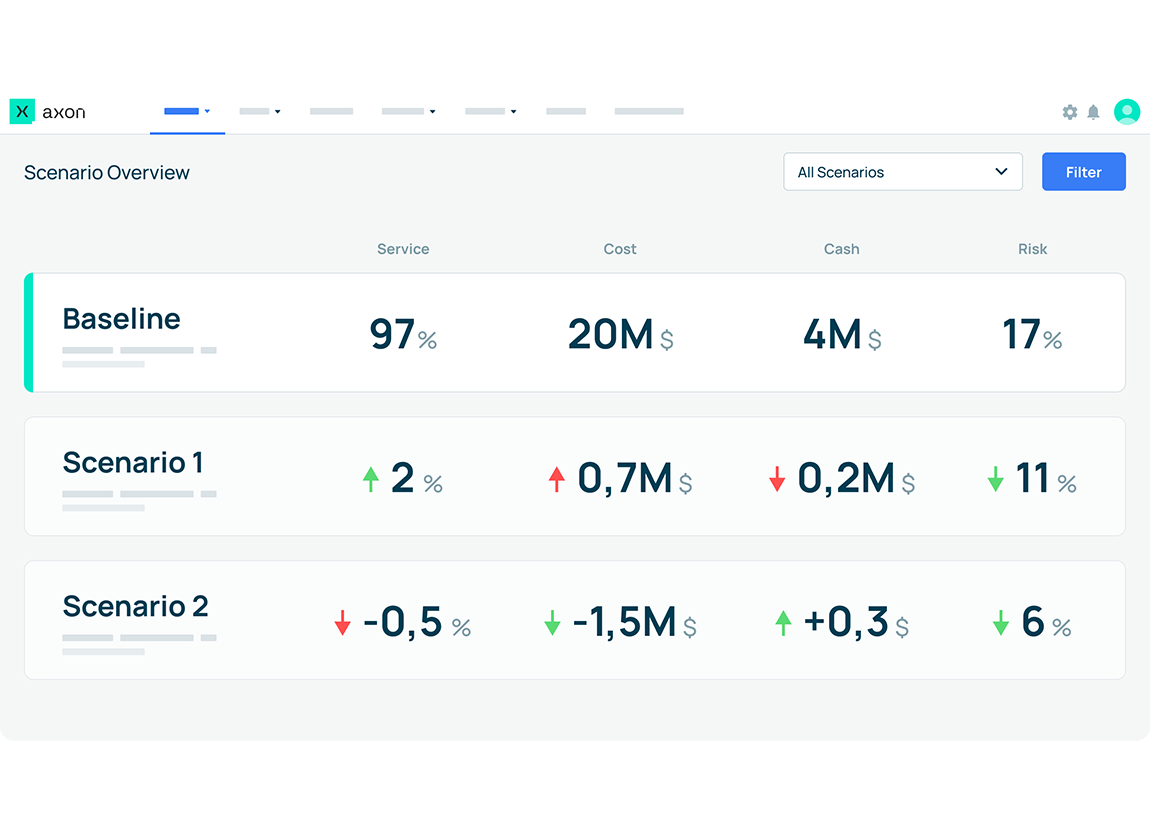

Axon Decide: Probabilistic simulation

Axon’s probabilistic simulation add-on, Axon Decide gives you the tools to optimize decision-making with smart projections. But it doesn’t stop there. Axon Decide empowers you to take those insights you’ve gleaned and put them to work in a fully operational simulation environment. You can simulate theoretical scenarios to conduct experiments, optimize your plans and mitigate risks. Axon Decide can answer questions about the E2E impact of certain supply chain events, which events require the most attention, what alternative actions you need on hand to accept demand and accelerate supply, the potential root causes and how to mitigate them.

Axon Control: Supply chain control tower

Axon Control is our automated and centralized supply chain control tower, which can turn insights into action. The data management suite helps you navigate your supply chain operations via intelligent analysis and actionable insights. It provides consolidated metrics, an automated alert center and smart assistance. With Axon Control, you’ll discover what your supply chain network looks like and its detailed product flows, if your planning master data reflects reality, where you can reduce E2E lead time, supplier adherence to your service level agreements and how much variability is in your supply chain.

A transformative tool for the modern organization

In this age of rapid technological advancements and evolving consumer demands, the importance of an efficient and responsive supply chain cannot be overstated. The concept of a digital supply chain twin has emerged as a ground-breaking approach, presenting organizations with an unparalleled capacity to mirror, monitor and manage their physical supply chain operations in real-time.

Here, we’ve illustrated the benefits of a digital supply chain twin, ranging from predictive insights to cost reductions through use cases and case studies. Whether a business chooses to implement the digital twin in-house or leans on the expertise of a SaaS vendor like Axon, the key to its success lies in a deep understanding of the nuances of the system and a commitment to integrating it seamlessly with existing operations.

The Axon platform is just one example of how businesses can leverage this technology, but it underscores the potential waiting to be unlocked. As we venture further into this tech-centric era, the digital supply chain twin stands out as a transformative tool, poised to redefine how industries function and thrive.

Take the next step in your digital transformation

Want to delve deeper into the revolutionary realm of digital supply chain twins? Curious to see first-hand how they can transform your operations with unparalleled efficiency and insight? Request a demo today to experience the dynamism and accuracy of the Axon platform in action.

For those ready to embark on this journey, Axon offers a free digital supply chain twin URS (user requirement specification) template to ensure you’re set for success from the get-go.

If you’re hungry for more knowledge before you get started, dive into a treasure trove of resources on the Axon website. From enlightening blogs, insightful articles and real-world use cases to impactful case studies and engaging webinars—we have it all curated for you. Elevate your understanding and be at the forefront of digital supply chain innovation. Take a tour around the Axon website and reach out to our experts with any questions you might have. We’re happy to help!