How wrong is your master data?

If you’re running a supply chain technology implementation, such as a footprint study or an APS implementation or MEIO, you’re likely trying to feed it master data. Gartner actually calls master data one of the most critical success factors of these programs. Are you confident in your numbers? Do you know how wrong your master data is? Well, for a start, Axon can show you the accuracy of your master data today. Then, it can show you how with a digital supply chain twin, it doesn’t have to be wrong at all. Let me explain how.

Expectations vs. reality

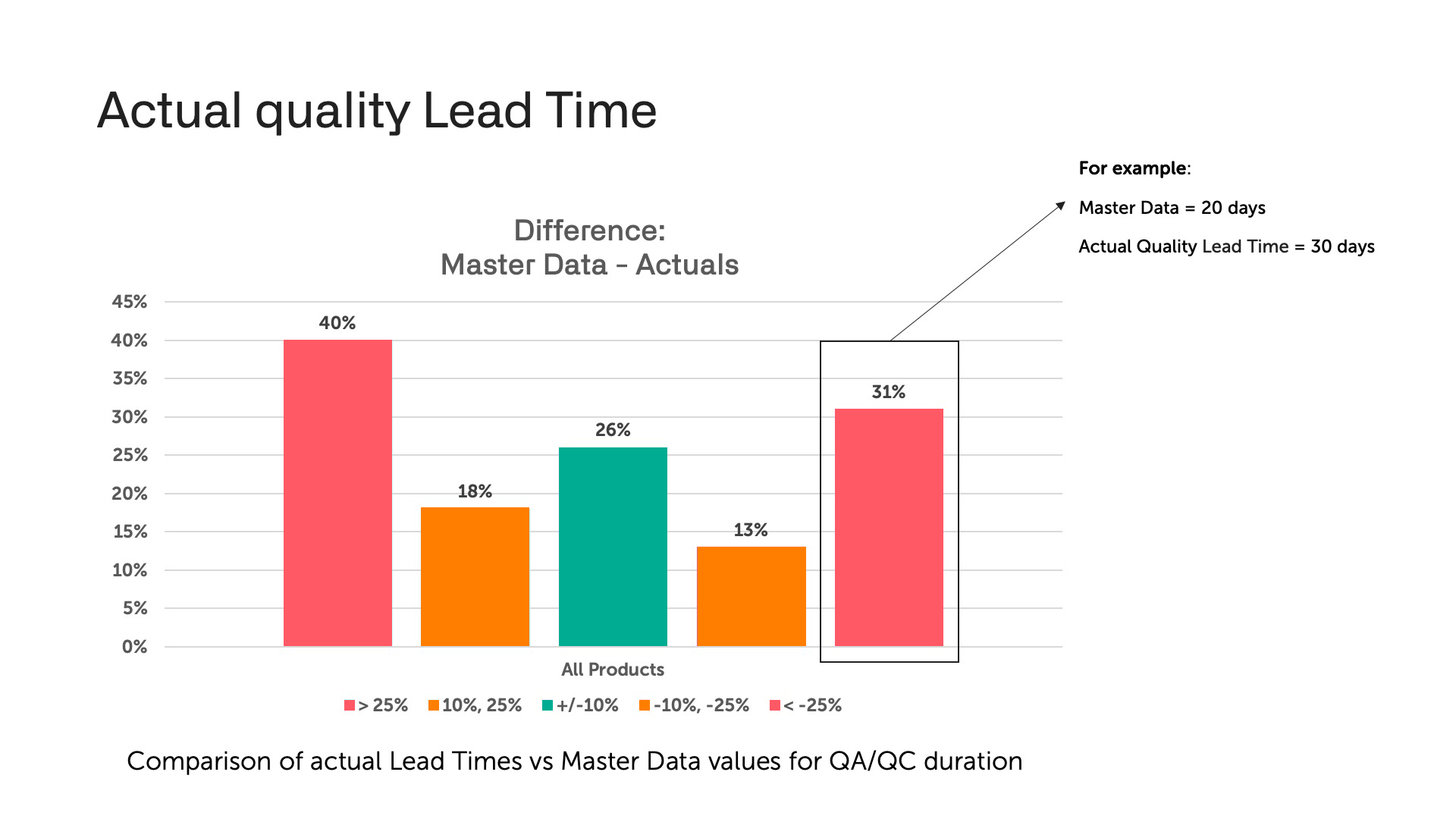

You should naturally expect to see a normal bell curve in terms of your master data accuracy, with low variation, centered around the mean and some deviations that don’t stray too far away from it. But, from what I’ve actually seen with global supply chain leaders, the reality is often more like an M-curve (see graph below). This is when the center is low and the left and right numbers are higher, with deviations greater than 25%.

When the master data is incorrect (and the deviations significant), this can lead to, among other issues, overstock and backorders. If materials and products have a master data lead time that is at least 25% greater than the actual lead time demonstrated through transactional data, this exposes a clear opportunity for inventory reduction. If the master data lead time is at least 25% less than the actual lead time, there is potential for a meaningful reduction in back orders.

Why is the master data wrong?

There are three key reasons that lead to incorrect master data.

- Lack of accurate information: Without access to good numbers, the data will always be wrong.

- Lack of time: When there’s no automation, stakeholders must make do with copying and pasting the available material. This leads to very rough data—and lost time.

- Human bias: This can come into play when using information and knowledge from a few years ago as a base reference. Further, risk aversions can lead planners to hold multiple buffers for the same risk, causing excess inventory.

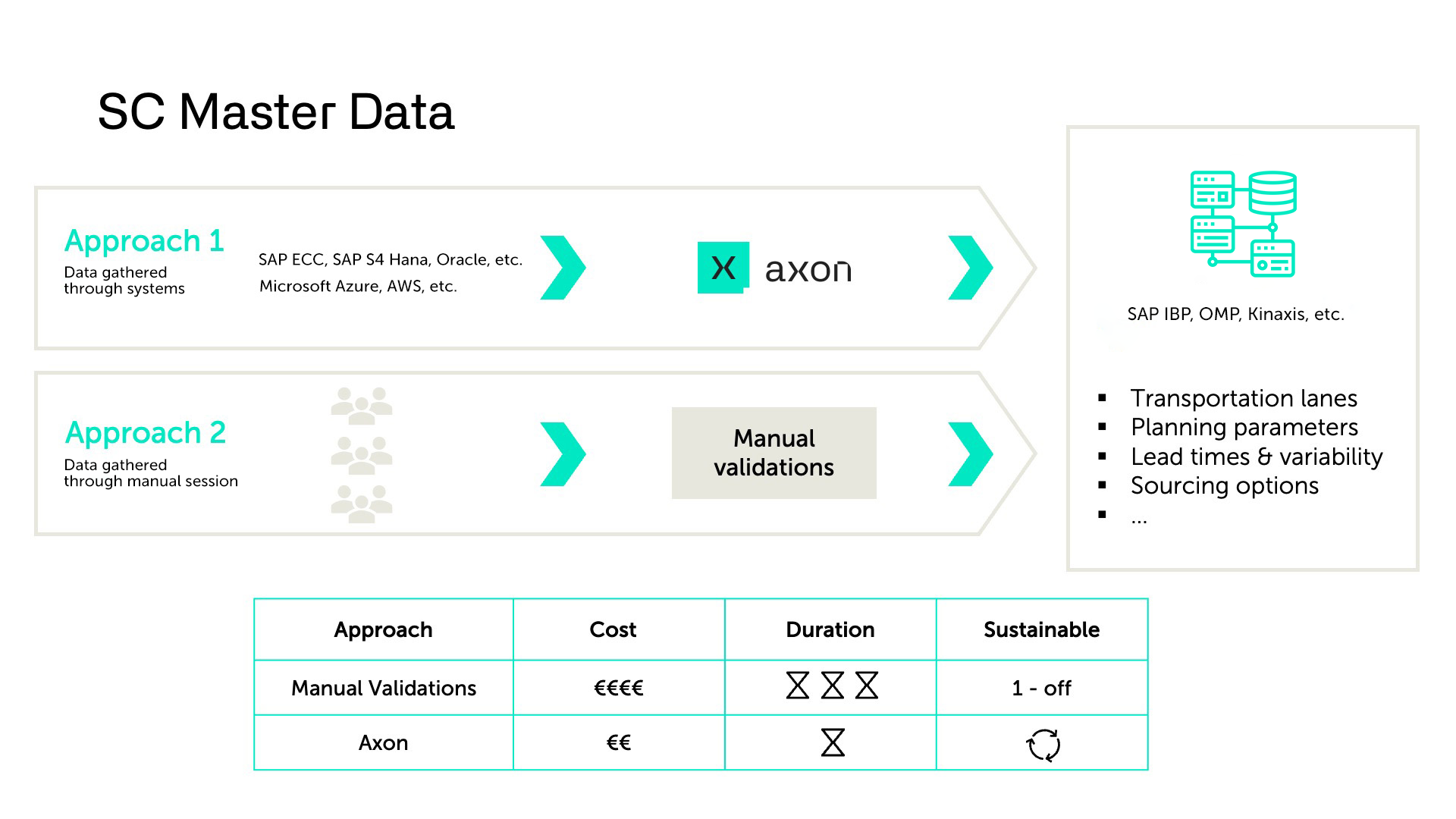

Better data with Axon

If your supply chain is currently using a manual method for collecting numbers, leading to wrong master data, it might be time to consider a digital supply chain twin. Axon’s technology automates the data collection and ensures high-quality input data to your supply chain systems. Gone would be the days of having to use an Excel sheet that pulls in data, then tries to transform it and conform to whatever master data you think is right.

Value creation by Axon

Did you know that bad master data can account for up to 15% of overstock positions? Why not eliminate the worries—and tangible costs—of having stock in the wrong place. And did I mention that a digital supply chain twin like Axon saves time? Think of all those hours a busy team can spend futilely trying to put together accurate data. And imagine what these team members could do with those hours, now freed up by technology.

Have I convinced you why a digital supply chain twin can be pivotal in master data improvements? (In fact, there are many ways a digital supply chain twin like Axon can make a difference for your business, some of which are pointed out in a blog from earlier this year by Axon VP Valérie Vandenbroucke).