How to realize multi-million inventory savings through a digital supply chain twin

Are you keen to find inventory savings for your supply chain? I think it’s safe to say you’re not alone. Finding these savings is a top priority for many companies as they strive to secure target service levels. Especially for industries in which service and on-time delivery are vital—like pharma—inventory management is essential. Planning and operations excellence, enabled by a digital supply chain twin, can pave the way.

2 keys to optimizing inventory

As we well know, inventory costs a lot of money. It’s an investment—from the goods themselves to their storage. And once that cash is spent on building the inventory, it’s locked. As goods like pharmaceuticals don’t stay viable forever, there is also the potential to lose money on stock that becomes obsolete. Money that could have been spent on future inventory or R&D, for example.

Thus, it’s imperative to keep your stock optimized. With the right quantity for the right product, at the right location, at the right time. How? With two keys to savings that are enabled by a digital supply chain twin: planning with the correct master data and operational excellence to shrink lead times.

Key 1: Validate your APS master data

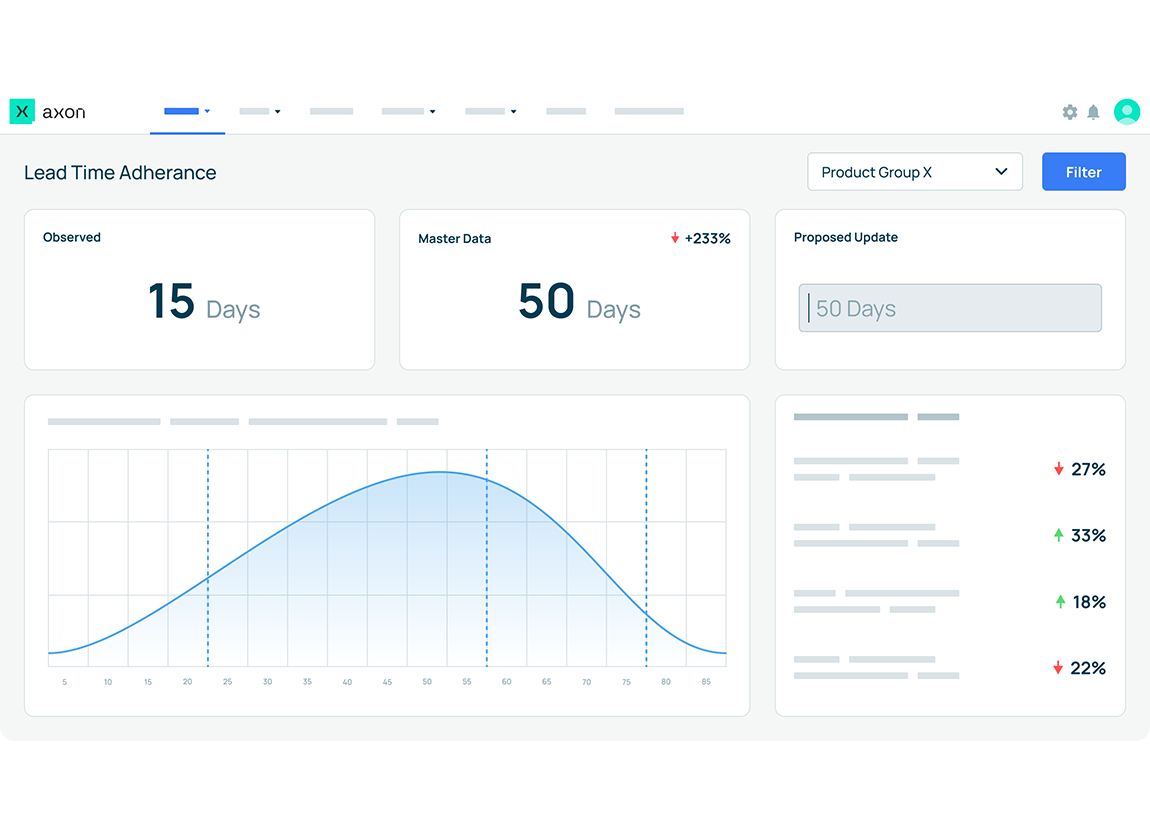

Optimal safety stocks are determined during the planning process. These safety stocks are calculated using such parameters as demand and demand variability, but also lead time and lead time variability. The latter two—provided by the master data in your advance planning system (APS)—are too often inaccurate or outdated, resulting in excess safety stock and lost money.

From experience, I’ve seen that many companies tend to focus on single-echelon (SEIO) or multi-echelon inventory optimization (MEIO) calculations to get their inventory levels right. While the focus of SEIO and MEIO is on the formulas, Bluecrux and Axon are focusing on the data that goes into those formulas. The more accurate the data input, the more accurate the calculation.

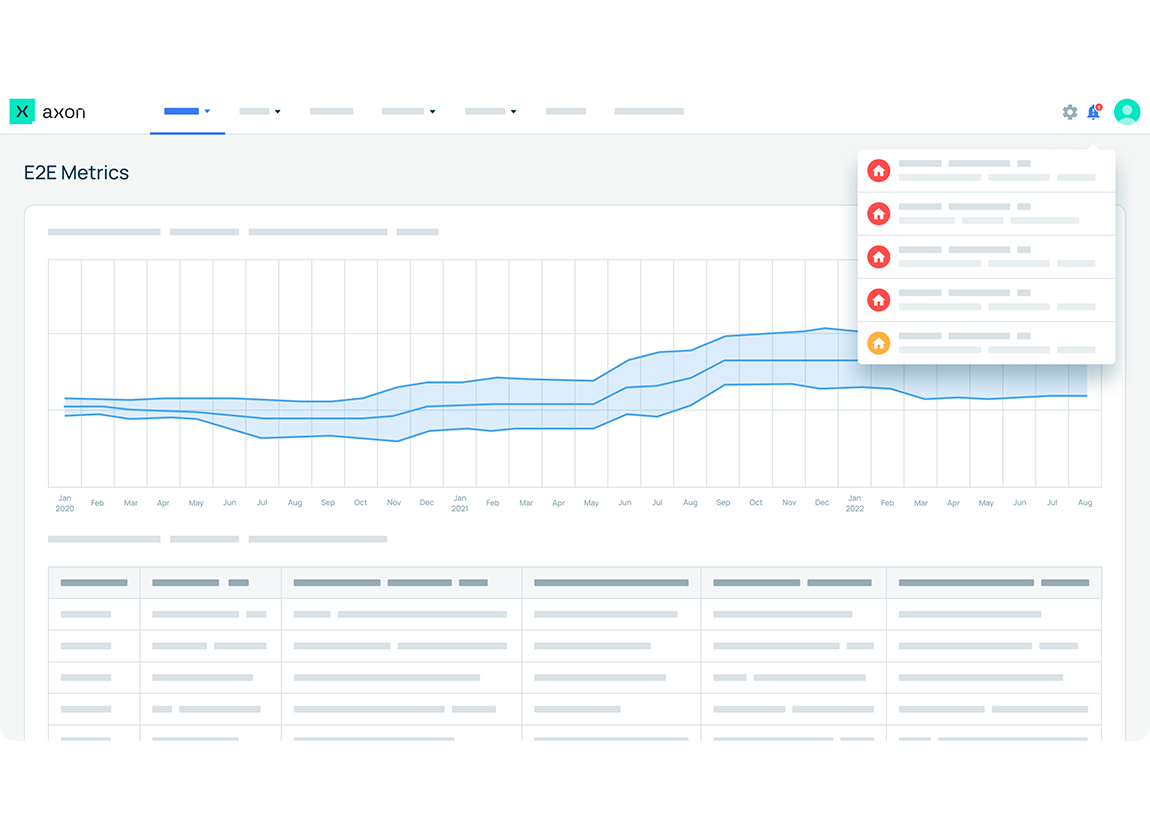

A digital supply chain twin like Axon can automatically compare master data with demonstrated performance, updating when necessary and creating a pathway to optimization. With parameters that better reflect reality, your safety stock can be reduced and will be more balanced, saving you a lot of money.

→ On average, companies using Axon have identified a 2% reduction in inventory. Depending on your inventory size, this could amount to millions of dollars in savings.

Key 2: Achieving operational excellence

If optimizing your planning master data is step one in managing inventory, achieving operational excellence is step two. Enabled by a digital supply chain twin, operational improvements could account for a further 3% to 5% reduction in excess inventory and a consequent boost in savings.

A digital supply chain twin unlocks information on lead times and lead-time distribution. It can identify potential operational improvements with the greatest potential financial benefits. And it can simulate the impact of specific improvements, helping you to track your progress.

→ A reduced lead time means that you need less stock, as your inventory is getting where it needs to be faster. In short, it means further savings.