PPM Summit Basel 2020: key takeaways

Binocs supports organizations in tackling one of the most critical challenges: proactively ensuring that the right resources are available, at the right moment, while avoiding too much administrative planning work. This is the key message that I communicated to the Annual Project, Program, and Portfolio Management Conference in Basel last Thursday (via video conferencing due to COVID-19). I used three real-life showcases to support my message. As some people were unable to attend PPM 2020, I thought: why not share a short summary of what was presented?

PPM 2020 – main lines of action

Showcase 1: resource management in regulatory affairs

“1,000 regulatory submissions translate into 15,000 concrete tasks.” Each of these tasks needs to be done at the right time and by the right competent team members. In other words, regulatory affairs environments need a digitalized resource management system.

However, as a single regulatory submission creates a multitude of tasks & sub-activities, it becomes next to impossible to manually create these tasks and be kept up-to-date on where you are in the process (what has been done, what still needs to be done).

We’ve solved this issue by enabling Binocs to synchronize with an organization’s RIMS system continuously. Our “operating model” intelligently and automatically translates the input from RIMS into properly sequenced demand, considering due dates, lead times, elasticity, … ready to start forecasting.

Showcase 2: use of ‘what-if scenarios’ in a TRD environment

A resource management system should enable organizations to make quantitative predictions about the resource capacity in the mid & long-term future: do we have enough resources to meet our workload or not?

What most resource management systems do not allow, however, is to deep dive into a potential capacity shortage: where is the lack coming from? And how do we fix it?

Binocs allows both: in a visually engaging interface, you can quickly identify what the capacity shortage entails (competence? Equipment? Availability?). Once you know where the shortage is coming from, it’s super easy to explore different potential solutions/scenarios like changing priorities & timelines, train to upskill team members, move staff, share equipment between teams, add external staffing, outsource tasks…. Planners can thus play around with different scenarios without the help of the ICT-department or external excel reports.

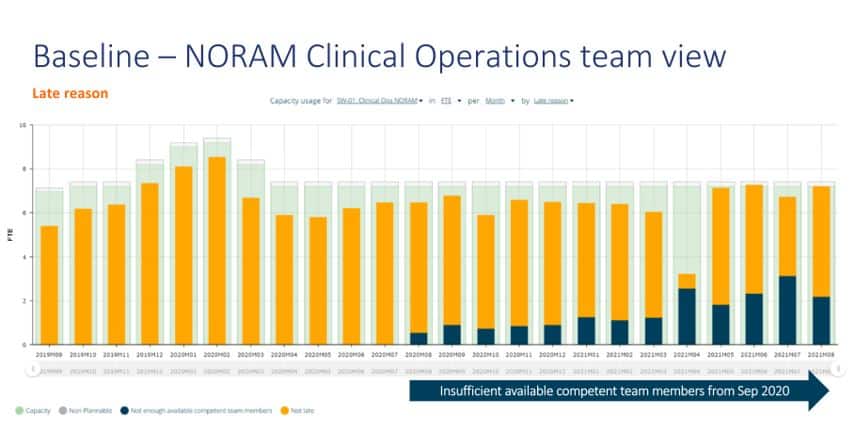

In one of the examples Frederik presented, this is how the ‘baseline’ capacity forecast looks like (blue represents a capacity shortage due to a lack of competent team members):

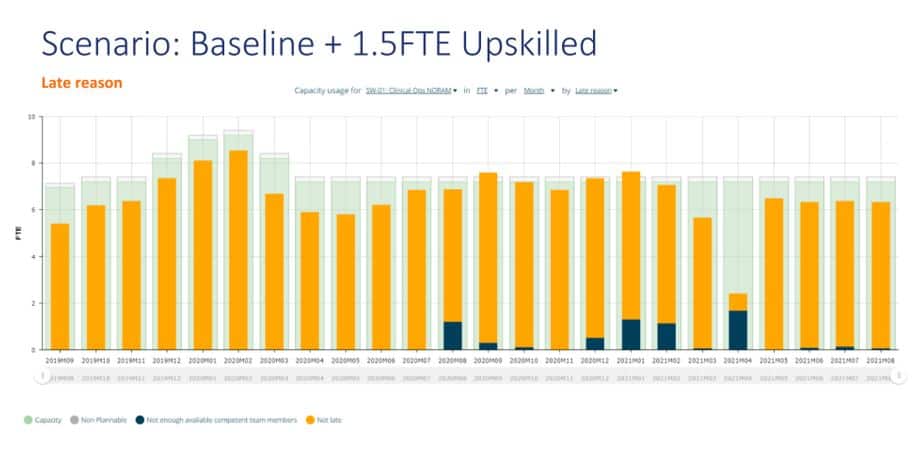

The user can then create a scenario where he/she upskills 1.5 FTE to explore if that would solve the problem. As you can see in the graph below, the blue color is melting away – it solved part of the problem.

Showcase 3: from capacity planning to detailed scheduling in a global development group

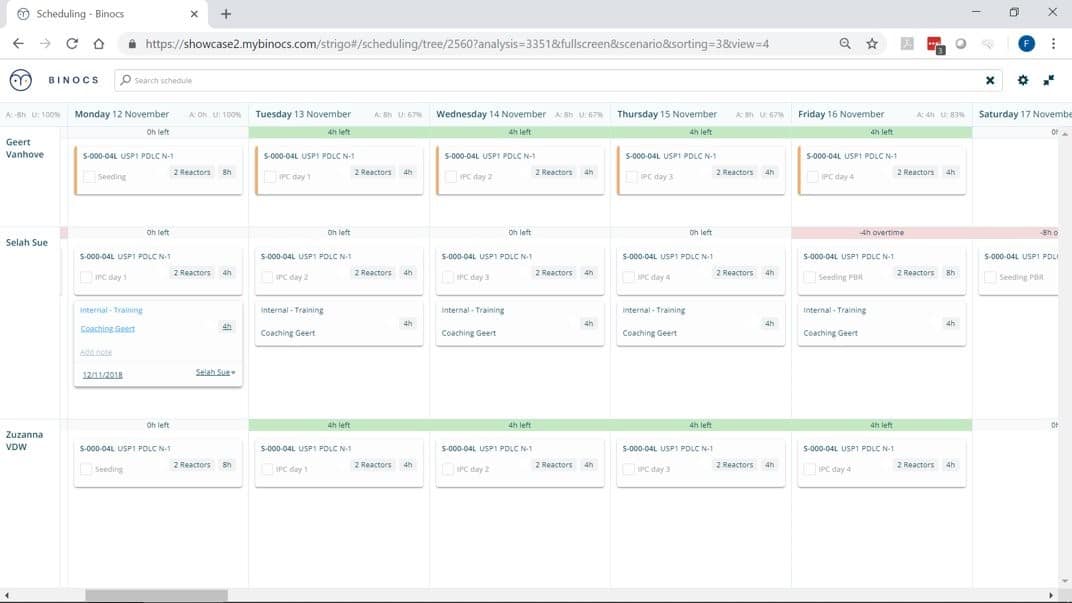

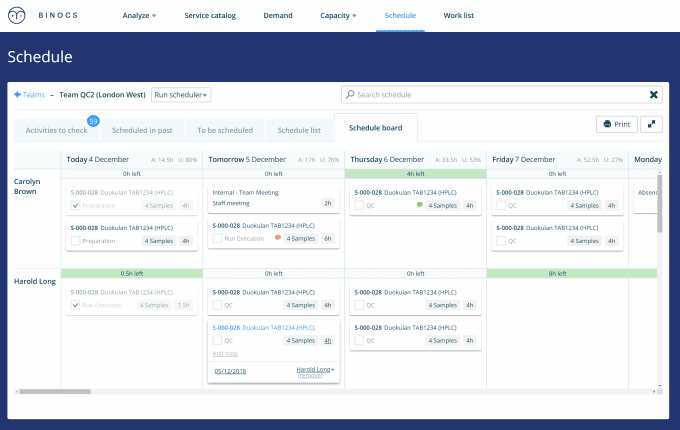

The third example showcases why Binocs is a unique resource management system in a global development group: in a single corporate system, you can forecast long term capacity, run quarterly capacity reviews all the way down to schedule on a daily basis. On a corporate level, Binocs supports forecasting & budgeting of resources. On the lab level, the daily scheduling interface in Binocs is a digital version of the physical planning board, supporting the transformation towards the digital lean of your labs. This is how the automatically generated schedule looks like in Binocs, which can be further fine-tuned by the planner:

Stay safe and healthy!

Related posts

-

Regulatory affairs: playing at the end of the game puts on extra pressure. Regulatory submissions in life-science industries are the most critical milestones in a new product development process…Read more

-

Into the multiverse: predicting lab outcomes with Binocs ‘what-if’ scenario analysis

Let’s explore how what-if scenario analysis (WISA) can be used to help predict outcomes and mitigate risk in pharma capacity planning.Read more -

Binocs digitalized our Lean Lab way-of-working

Business context In 2014 we implemented the Lean Lab methodology. This enabled a major breakthrough in performance and throughput. In the past few years, we see a significant increase…Read more

Frederik Jaenen

Frederik is VP of Sales at Binocs and has over 25 years of experience in laboratory systems, including as a Project Manager for major LIMS rollouts at various global enterprises. When he joined Bluecrux in 2017, his experience and business development skills significantly boosted the commercial success of Binocs.