Binocs digitalized our Lean Lab way-of-working

Business context

In 2014 we implemented the Lean Lab methodology. This enabled a major breakthrough in performance and throughput. In the past few years, we see a significant increase in demand variability, both in products as in volumes. We have reached a point where the existing Lean Lab method becomes hard to maintain.

Cooperation between Binocs and Lean Lab – improvement potential

We need to react faster to priority changes and the manual magnet plan board doesn’t cut it anymore. We start to see performance drops. Time to make the digital move.

We screened the lab vendors and the internet for digital plan board solutions. Most of them are manual plan boards, which do not add much value compared to the magnet plan board. LIMS vendors such as Labware, Labvantage, and Thermo Fisher do not offer planning solutions for analysts and instruments.

APS vendors (Advanced Production Scheduling) applications that are used in supply chain offer constraint-based planning, but they focus on material flow and not on the analysts. The entry threshold is way too high for team leaders in a QC lab.

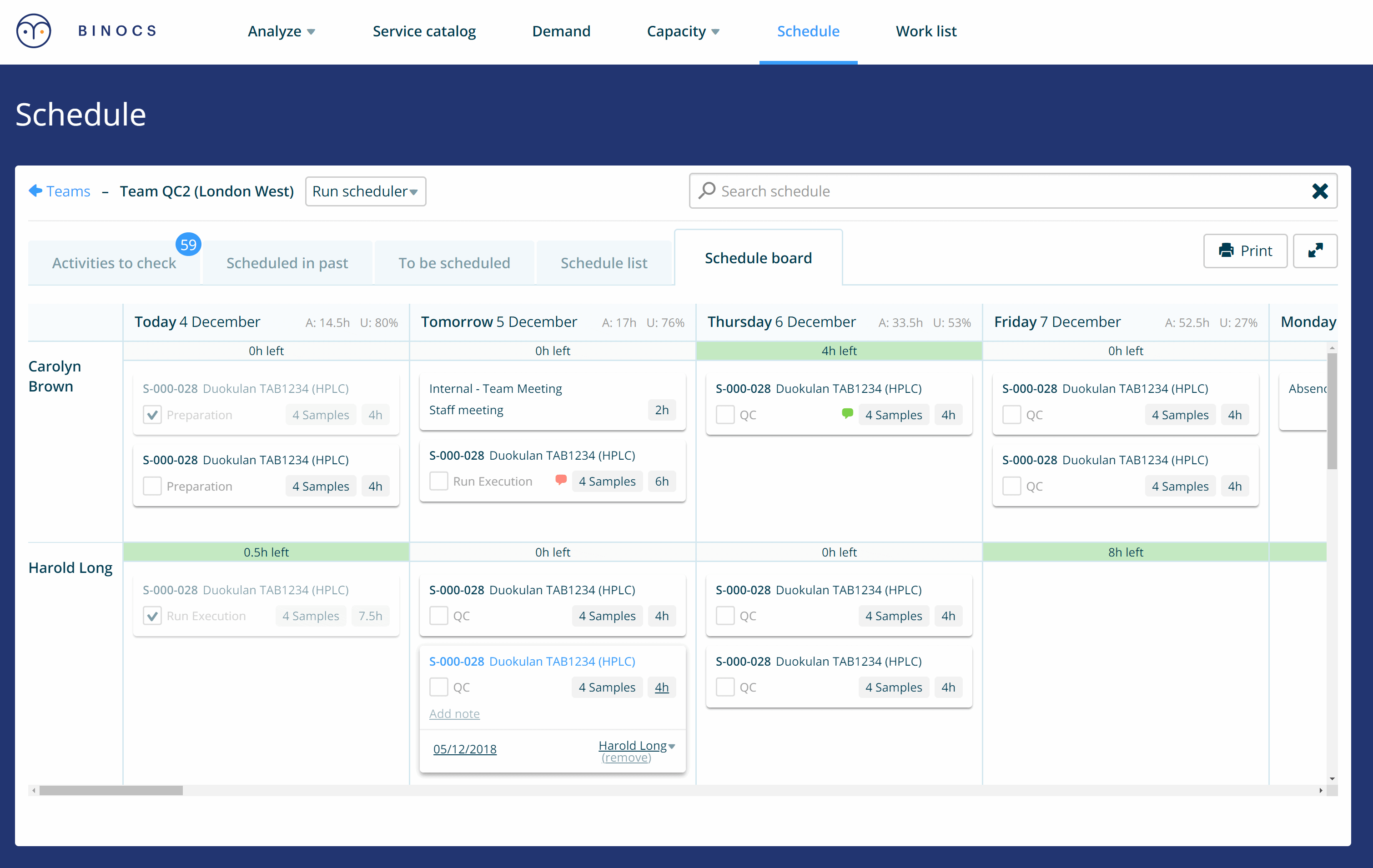

Binocs was the only solution that fully met our requirements. It is the only solution that has a constraint scheduling algorithm that takes into account instruments, analyst availabilities, preferences, and qualifications. It also lets the team planner lock certain scheduled activities while Binocs can fill the white space to optimize throughput and on-time QC release.

How Binocs helped

We could import the LeanLab roll cards and rhythm wheels directly in Binocs with the upload tool that comes with the solution.

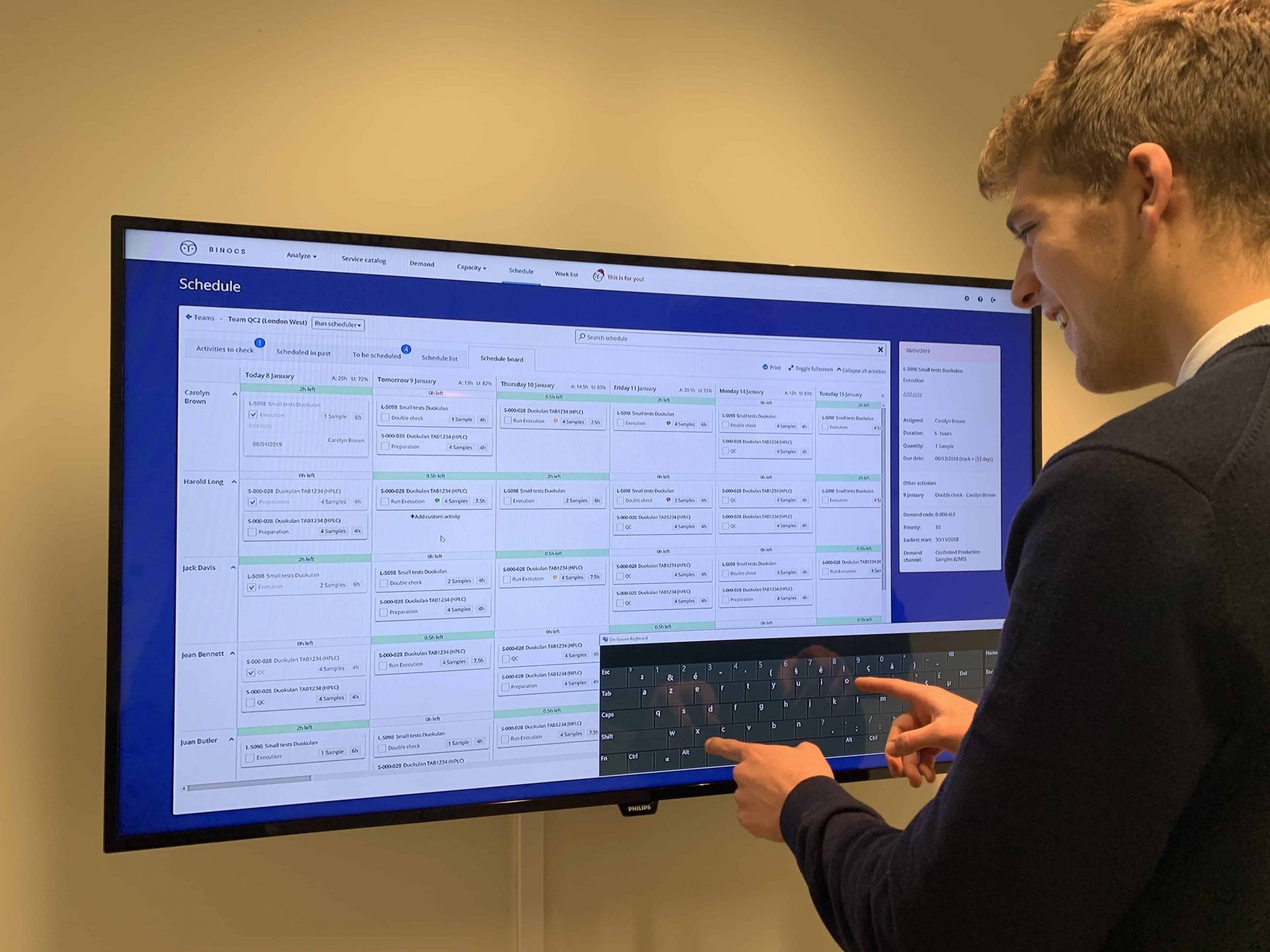

Binocs reads the test demand and samples directly from LIMS and combines this with the QC release priorities obtained from Supply Chain. We run Binocs scheduling daily to reflect the latest situation. Each analyst has a graphical worklist. By simply checking the tick box, the analysts can report progress. The Binocs plan board is also displayed on large flat screens in the lab.

The Binocs Scheduling application co-exists with our LIMS. The Binocsworklist might contain activities that are not managed through LIMS (e.g. time to contribute to an Out-of-Spec analysis).

The time spent by the team planner is reduced with more than 50%, while QC release throughput has increased.

The best part is that the Binocs schedule seamlessly blends with capacity planning and forecasting, which gives us full visibility.