Improving Lab Throughput and Planning Adherence in QC labs – the figures

This year we participated in Future Labs Live for the first time. This conference is the world’s most multidisciplinary event for R&D, quality, and manufacturing laboratories and I was able to present quantifiable evidence for the value of implementing Binocs at QC laboratories. I presented insights from our research based on data from some of the top 20 big pharma companies globally. The key message? “Binocs supports organizations in optimizing lab planning adherence and throughput!”

How Binocs improves lab efficiency

We’ve been busy over the summer! Our colleague Adam and our intern Lauren (graduating as a master in statistics), joined forces to deep-dive in Binoc’s historical data, in pursuit of answering an, at least for us, exciting question: just how much does Binocs improve planning adherence & throughput in QC labs?

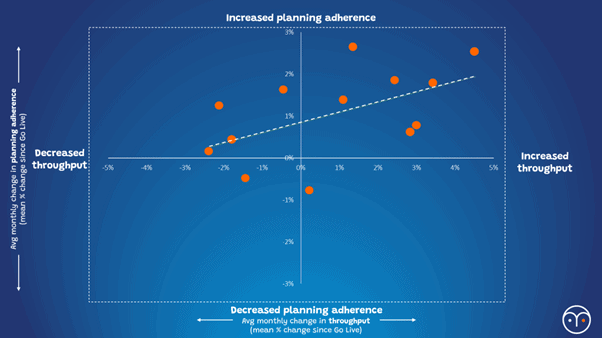

Quite a few companies have been using Binocs for quite a while now. That means that the historical data in Binocs is rich and robust. Through statistical analysis and several research steps (please let us know if you want the details), we were able to map various teams on a two-axis:

- The monthly average increase in throughput since they started using Binocs(x-axis).

- The monthly average increase in planning adherence since they started using Binocs (y-axis).

What you can see on the above graph is that almost all the teams included in our research saw their planning adherence increase since the implementation of Binocs. In the presentation, we took some time to discuss each quadrant separately, to explain why these teams achieved the results they did.

The most exciting result…

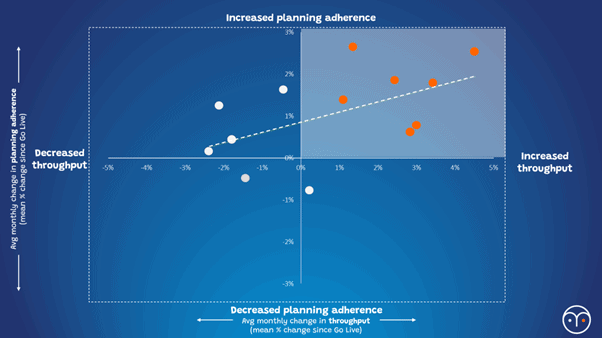

But, probably the most interesting quadrant is the right top one.

These teams saw BOTH their planning adherence & throughput increase since they started using Binocs. This could be surprising to some, as often planning adherence and throughput are considered to be contradicting forces (as explored in more depth in this blog).

Increased Throughput and Planning Adherence

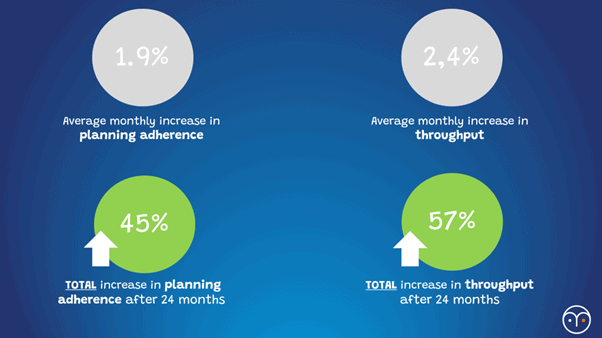

The graphs above show the monthly average increase. If we zoom in on one random team in the right top quadrant, we see that:

- Using Binocs, they achieved a monthly average increase in planning adherence of 1,9%, which equals a total increase in planning adherence of 45%.

- Using Binocs, they achieved a monthly average increase in throughput of 57%, which equals a total increase in throughput of 57%.

Digitalizing lab processes using a co-bot

Pretty impressive results, right? Now, the question is: what is the underlying reason for these results? To answer that question, we need to go back to why these companies started using Binocs in the first place.

And to keep it short, the key reason is: if you want to consistently and optimally plan and schedule resources in a QC lab (and thus optimize adherence and/or throughput), you soon realize your biggest opponent is the human brain. That’s because:

- There is too much information, and too many variables to keep track of.

- The information is scattered across the lab; it takes a lot of time to centralize and keep it up to date at all times.

- The need to manually re-schedule when facing unexpected events (someone calls in sick in the morning, high priority samples come in, …) is time-consuming and rarely results in an optimal schedule.

Binocs aims to tackle these challenges by digitalizing the process. And Binocs is a co-bot, which means: it automates some processes that are simply too complex for a human brain to handle, but in the end, the human planner can still make manual changes and thus stays in control.

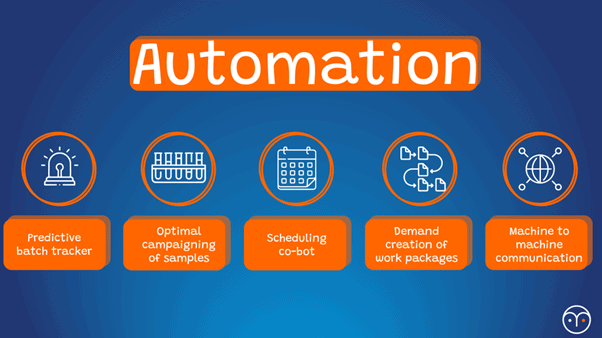

Whic parts of the process does Binocs automate?

We ended our presentation with the 5 areas where the ‘co-bot’ supports the optimization of planning adherence and throughput.

- The predictive batch tracker: reports & dashboards. For example, in the Batchtracker dashboard, you can see, per production batch, if a batch will be: late, late but you can still reprioritize tasks to make sure it’s released on time. Click here for a more in-depth exploration of the value of the predictive batch tracker.

- Optimal campaigning of samples: Binocs can automatically group samples into campaigns, based on business rules that you can define.

- Scheduling co-bot: Binocs can propose a schedule automatically, taking into account availabilities, equipment, competencies, priorities, due dates… The human planner can make manual changes (stays in control).

- Demand creation of work packages: think about 200 stability studies for example, which translates in a total of 6000 tests that need to be assigned to the right team at the right time, … Imagine that you’d need to create and set all that demand manually. Instead, You can learn Binocs what needs to happen to complete a stability study, and then automatically generate the demand, nicely sequenced, across different functional teams.

- Machine-to-machine communication, which means that Binocs can continuously synchronize with external systems like LIMS, ERP, Excel, … and this, of course, has two benefits: no double entry, but actually the first step towards zero input.

Related content

-

There are two wolves inside your QC lab: planning speed vs efficiency. How can you tame these beasts and find the perfect balance?Read more

-

4 KPI dashboards that every QC lab should use

KPI dashboards in QC are crucial as they enable lab personnel to see relationships between different metrics and make informed decisions about how to optimize lab performance. Based on…Read more -

Exploring the value of lab KPIs: due date adherence

By monitoring due date adherence metrics & making operational adjustments, teams can optimize their service level, making it a crucial lab KPIRead more

Mathias Lasoen

Mathias is the Head of Growth Marketing for Binocs.