How digitalization makes QC resilient in turbulent times

Pharmaceutical companies evolve all the time: they re-restructure, expand, switch from a daily regime to an early/late shift regime, consolidate operations, and much more. These evolutions can be sudden or more spread out, can have a minimal or big impact. But, regardless of the type or magnitude, you need to make sure you maintain an overview of your lab capacity: what additional demand will be coming in as a consequence of this change? And how does it impact the resources available to do the work? Digitalizing quality control operations with a specialist scheduling and capacity management tool makes QC labs a lot more agile in effectively dealing with complex business dynamics.

QC digitalized scheduling methods based on real-life business case

Let’s zoom in on a client that started using Binocs’ QC digitalized scheduling a couple of years ago. During that period, they transformed from a small molecule plant into a biologicals plant. The impact of that re-structuring was significant:

- Teams needed to be re-organised

- Additional lab infrastructure was needed

- New test methods were introduced

- The QC lab doubles in headcount

And regardless of the expansion, the supply chain doesn’t wait for the QC lab to organize. “QC lab, you’d better be ready for the heavy weather!”

Benefits of QC digitalization – examples

This client implemented Binocs in 2017, which helped them to absorb & adapt to that reorganization and growth relatively easy. The two main reasons to implement capacity planning and scheduling were:

1. Growth should not impact productivity

X Our client was going through a massive site reorganization. Their ’lean on paper’ approach was not flexible enough; it was too rigid. Operational Excellence teams were facing a never-ending story of adapting timecards, whiteboard magnet strips and the like. What was intended as a methodology for efficiency, turned into a counterproductive effort.

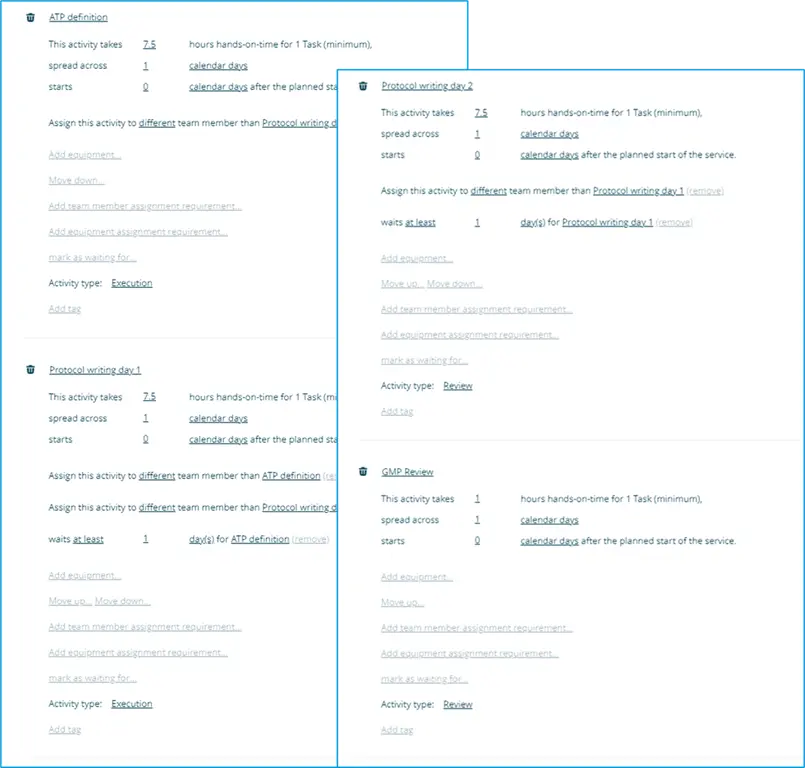

V Instead, the solution for QC labs was to digitalize their lab planning and scheduling. Whenever business rules or operating models change, now or in the future, they simply change this in Binocs and start scheduling again.

2. Carefully plan re-organization and expansion

X “We have 3 new product introductions, so we need to hire 5 analysts to meet the additional demand.” That’s a straightforward solution, but is this the smartest approach? The lab complexity reached a level that did not allow for intuitive decision making anymore.

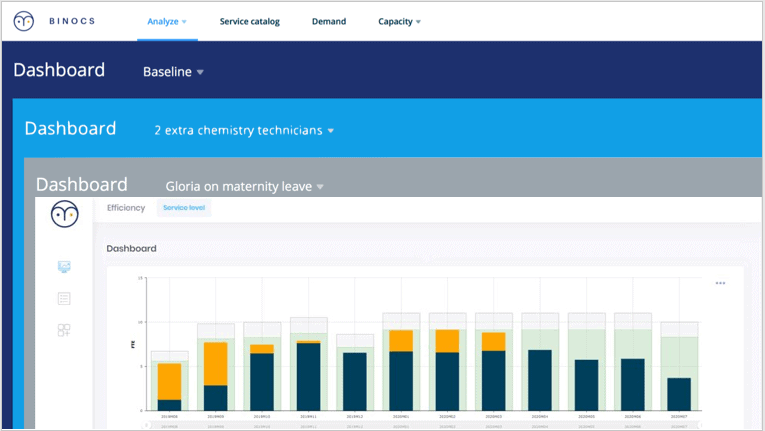

V What if we re-structure our lab capabilities across multiple teams? Can we train our analysts? What if we share resources across teams? Our client now uses what-if scenario’s in Binocs to explore the impact of those potential solutions. This means they can carefully and intelligently plan their re-organization with expert knowledge & benefits of QC digitalization.

In summary

As your organization is changing all the time, make sure that scaling your QC scheduling, digitalization and capacity management system is as easy as it can be. In Binocs, you can test your future operational expansions in your lab virtual twin before implementing it to align with the ‘new reality’. Literally, in a few clicks: add teams, define new competencies, add new test methods, share people with other teams, switch to shifts, … And off you go.

In short: Binocs is a sustainable, reliable QC capacity management solution that scales alongside your organization now and in the future.

Want to know more? Request your demo!

More on capacity management

-

Why is capacity planning so often reactive rather than proactive? Solving capacity problems before they happen is easy with Binocs.Read more

-

The lean lab goes digital: 6 ways Binocs increases QC laboratory efficiency

Increasing efficiency in QC labs is tough—but digital is making it easier. Learn 6 effective and proven methods for improving QC performance!Read more -

Merck KGaA uses Binocs to increase their QC performance

Top 20 pharma company, Merck KGaA, uses Binocs to manage capacity planning in QC labs. Find out why we’re the perfect choice for your lab tooRead more

Mathias Lasoen

Mathias is the Head of Growth Marketing for Binocs.