4 examples of intelligent implementation: Binocs at PLA2023

Last week I was privileged to speak at this year’s Paperless Lab Academy (Europe) in Lake Maggiore, Italy. As the PLA is the premiere event for discussing innovations in lab data management, digital transformation, and paperless processes, I thought it was a great opportunity to present more information on the Binocs theme of “intelligent implementation” in lab digitalization, including 4 examples of intelligent implementation in practice!

I’m delighted to confirm that the workshop was enthusiastically received and, as such, I’d like to briefly share the key points with you in this post.

In a rush? Here are the 3 key takeaways

- 👉 Going paperless is about more than just saving paper—it’s also about optimizing operations by fully capitalizing on the features digital systems offer that manual pen-and-paper processes do not

- 👉 Many labs see digitalization as replacing manual processes with Excel analogs, which ends up taking more time and being more complicated to manage

- 👉 Using Binocs for automated planning and scheduling helps to bridge the gap between traditional paper-based approaches and AI-enhanced systems, delivering significant performance enhancements in the process

Intelligent implementation

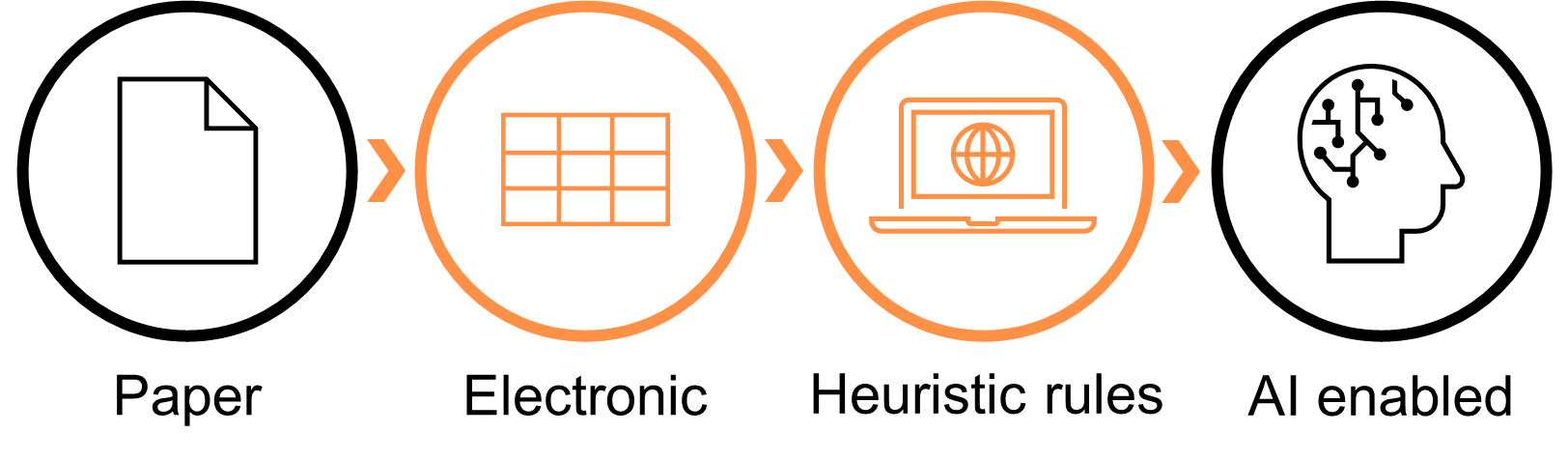

As recently outlined in our blog, the best way to deliver paradigm-shifting new technologies is rarely by building a 1:1 analog of the existing dominant approach. Indeed, existing, human-centered logic is not always easy (nor practical) to translate into digital systems. Despite this, many laboratories that are transitioning to a paperless setup can view digital-enablement as simply substituting pen-and-paper processes with their direct computerized equivalents, rather than fully capitalizing on the advantages of the new tech. As a result, the gains of digitalization aren’t always felt and optimism for the future of digital labs can be dampened. This, in turn, can make discussions around the future role of artificial intelligence in labs feel distant and disconnected from the reality on the ground.

Nevertheless, in many respects A.I. is already here and will certainly become more central to lab operations over the coming decade. As such, I would suggest that any intelligent approach to digital transformation in laboratories must serve as a bridge between the old paper methodologies and the future of A.I. enabled processes.

Going paperless is about more than just saving paper! Below are 4 brief examples of how Binocs delivers on our commitment to intelligent implementation. Join us as we build a path towards the future of digital labs via our automated and A.I. enabled planning and scheduling solutions to enhance laboratory performance.

Example 1: Sharing equipment between departments

When 2 departments (e.g. Production and R&D) share equipment and therefore require planning coordination, the established system for most labs has been to employ an IT supported work flow to book time on a device using a third party system (such as MS Outlook). This manual process has to be factored into wider planning and, by necessity, operates on a first come, first served basis without any feature or priority management. While moving to an online system like this for reserving equipment is a form of digitalization, it does not take full advantage of the technology.

The alternative? With Binocs, we deployed a centralized system for all planned R&D activities, including equipment sharing, that:

- Allows Equipment reservations by R&D to be automatically updated

- Books slots based on up-to-date availability, accounting for prioritization

- Improves equipment utilization via workload leveling

- Delivers fully-customizable reporting on equipment usage/availability

Example 2: Optimizing team schedules

If, for example, a CRO has multiple teams of 15-20 analysts to schedule, the standard approach is to develop a strategic, tactical, and operational planning process, which is then manually orchestrated (usually via complex Excel workbooks). This is then followed by a weekly race to distribute the schedules across the analysts and deliver the manual operational plan to each lab team/section separately. Again, while this approach is, indeed, digital and paperless, it fails to capitalize on the potential of computer systems and instead stretches the functionality of a technology (spreadsheets) beyond its intended use.

The obvious solution is therefore to use a digital system that is purpose-designed to deliver optimized scheduling. With Binocs, the CRO can:

- Deliver an operational plan created via an A.I. algorithm and optimized across multiple lab teams

- Improve workload leveling across teams

- Define constraints so that tasks are automatically assigned to the right people

- Configure the preferred way of working (e.g. stick to my specialty, stick to my project)

- Continue to manage and gain insights into sub-team operations

Example 3: Weekly schedule for scientists

Scientists need a stable plan for at least the next week, which typically means using multiple tools—potentially one per team—each with a different structure and logic for assigning work. As a result, additional training is required for people moving from one team to another and there is generally less transparency and harmonization across the different teams.

By contrast, planners using Binocs can easily:

- Automatically build a schedule that accounts for E2E project steps

- Deliver up-to-date plans for and by the scientists themselves

- Block-out a plan one or more weeks in advance

- Accelerate coordination and communication

- Distribute workload evenly and fairly

- Integrate with HR systems to automatically plan for annual leave, etc.

Example 4: Moving from rhythm wheels to dynamic scheduling

In pharmaceutical manufacturing, test batches must be rapidly analyzed so the product can be released to market. Historically, drug substance QC testing has often been planned based on long term (6 week) rhythm wheels, with a separate plan for each product. Such a fixed rhythm depends on a predictable sample plan (with some contingency to allow for day to day variation) and making additional optimizations or adjusting to unexpected changes is complex and time consuming.

Because unexpected changes are a common feature of the pharmaceutical release cycle, it makes more sense for planning to be handled in a dynamic and automated fashion, rather than simply adopting a fixed, manual approach with a digital system. That’s why Binocs provides:

- Dynamic scheduling based on received and expected test samples

- Effortless daily campaigning, recalculation and rescheduling

- Greater asset utilization

- Capacity optimization

Are you interested in learning more about how Binocs can support and enhance your laboratory operations through our intelligently implemented digital solution? Why not reach out for a chat today?!

Talk to us about Binocs in your digitally-enabled lab today!

Explore our related content

-

This post explores the new personalized Binocs landing page feature and how co-creation principles were central to its design.Read more

-

4 KPI dashboards that every QC lab should use

KPI dashboards in QC are crucial as they enable lab personnel to see relationships between different metrics and make informed decisions about how to optimize lab performance. Based on…Read more -

Towards a paperless future: the path to lab automation

Going “paperless” is about more than simply converting paper-based processes into digital counterparts. In this blog post, we will explore the critical steps towards achieving a paperless future for…Read more

Frederik Jaenen

Frederik is VP of Sales at Binocs and has over 25 years of experience in laboratory systems, including as a Project Manager for major LIMS rollouts at various global enterprises. When he joined Bluecrux in 2017, his experience and business development skills significantly boosted the commercial success of Binocs.