3 key challenges for biopharma process development labs, and how digitalizing their lab helped them: a use case

Clients rely on Binocs to plan and schedule knowledge workers for process development, clinical batch production, service labs… because it assures that the right competent resources and equipment are available at the right time. A multinational biopharma company that already uses Binocs in a couple of their QC labs, looked at us for a digitalized solution for their biopharma process development labs. These labs execute small-scale biopharma manufacturing processes, a combination of upstream, downstream, and analytical lab activities, and receive demand for experiments from project engineers.

Pre-digitalizing: relying on Excel

For this lab, scheduling and resource management is a complicated endeavor. MS Excel was their go-to software to model business processes and manage resources.

- Multiple master Excel files, fed by a multitude of other Excel files: project request, resource availability, planning.

- A lot of different sources = a lot of non-value-added time to create and to keep them up to date, errorless and aligned.

3 unique challenges, and why they needed to digitalize

There are three unique characteristics making scheduling & managing resources challenging here:

1. Highly dynamic demand

Challenge: Every experiment that is requested at the lab is somehow different from the previous one.

Solution: Binocs allows you to model your experiments in detail. Within each service, you can create a multitude of activities like process steps, analytical testing, documentation & reviews. For each activity, you can add detailed constraints. For example, “harvesting needs to start exactly 6 days after seeding is completed” or “the review cannot be performed by the same person that performed the viability test”. Templates can be made and shared. Actual experiments can differ from the template that was used.

2. Upstream processing activities need the right equipment at the right time

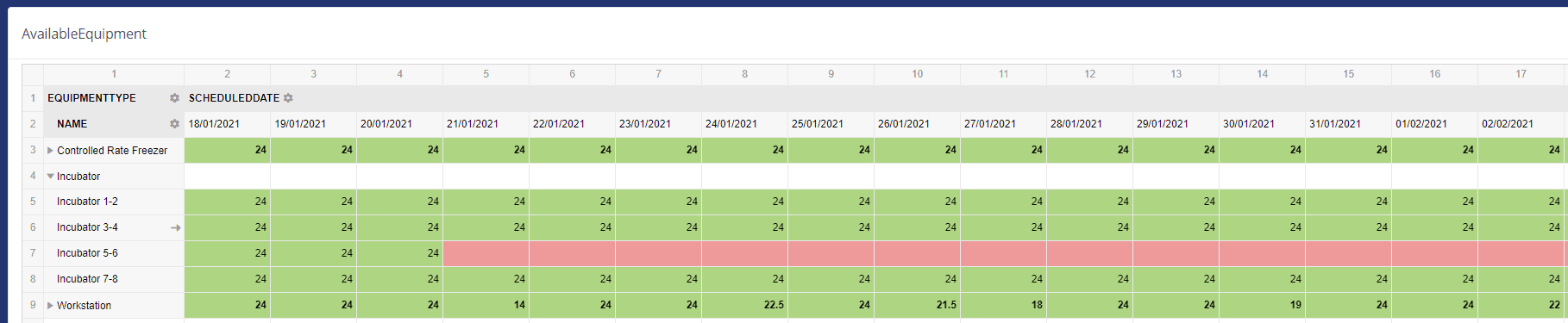

Challenge: This is an equipment-intensive process (flasks, wave bags, different types of bioreactors…), and the planner needs to be 100% sure the right equipment will be available at the right moment to execute the seed train without interruption.

Solution: With an equipment plan-board, Binocs gives immediate visual feedback if key equipment (the seed train) is available to confirm new experiment requests (capable of promise). Based on that feedback, the planner can propose to change the start date or find other solutions.

3. The need to remain flexible & agile

Challenge: Even though the process has many different steps such as analytical testing, documentation, and reviews, and each step requires specific competencies (and sometimes specific equipment), the puzzle needs to remain flexible & easy to plan.

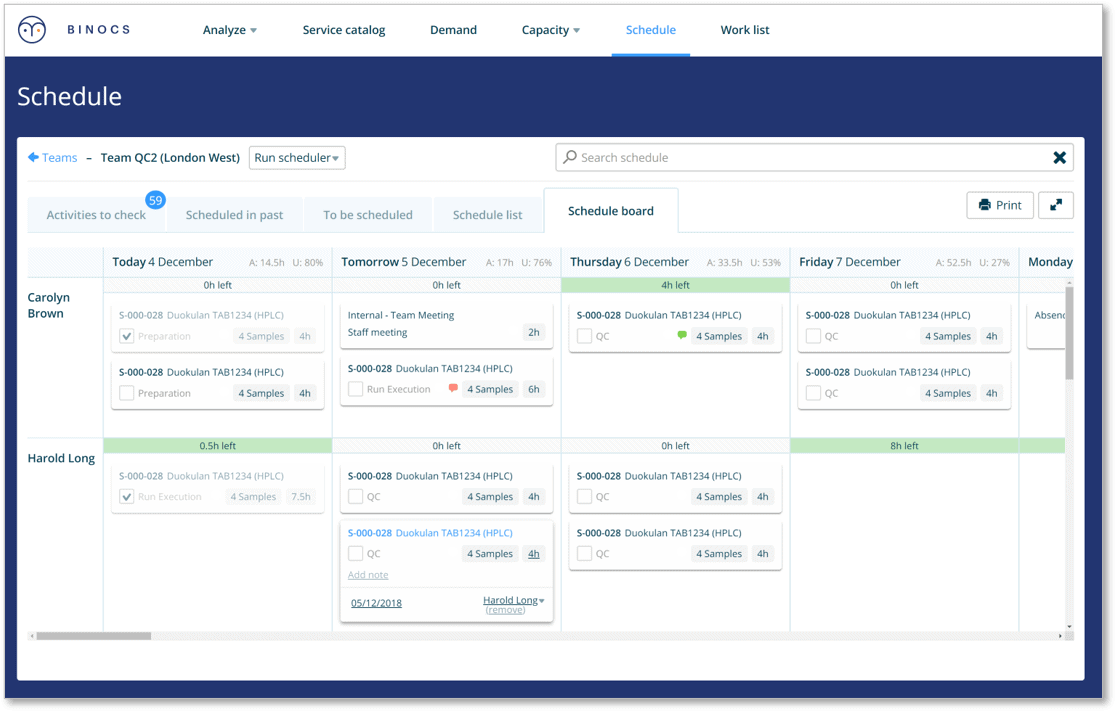

Solution: The Binocs planning co-bot takes over the Excel-scheduling: it automatically generates a digital schedule board for people and equipment. The planner / lab-manager remains in control, but now has more time to focus on what really matters: optimizing the utilization rates, reacting to last-minute changes (e.g. harvesting on purpose 1 day later…).

In summary

With the integration of Binocs, a new planning approach is introduced with the possibility to:

- Execute requested experiments without delay and surprises.

- Detect opportunities to add additional experiments if the equipment is available.

- Report on resource usage looking backward and forward.

- Make planning available & visible to all stakeholders.

Do you want to know more about our specific use cases? Check out:

- for QC Labs,

- for R&D,

- for Cell & Gene Therapy.

Are you looking to digitalize your lab? Request your free demo here

-

Find out why it’s not enough for labs to simply digitalize their manual processes and see whether you’re doing lab digitalization wrongRead more

-

Small-scale production with Binocs

Check out our blog post that briefly outlines how Binocs can successfully be leveraged to support small-scale (biopharma) production R&D projectsRead more -

6 KPIs positively impacted by lab digitalization

Digital innovations make labs more agile, reliable, compliant & efficient but how can you make lab digitalization work for you as a planner?Read more

Mathias Lasoen

Mathias is the Head of Growth Marketing for Binocs.