Digital lean labs: taking the next step with Binocs

Let’s explore the role of Binocs within the broader digital lean lab ecosystem. It is inspired by the “Digital Lean Lab” session organized by Ibec on 7 Oct 2021, featuring presentations by colleagues from Accenture, Astellas Pharma, and Bluecrux.

What is a “Digital Lean Lab”?

The broad principles of the Lean Lab are rooted in process optimization to deliver efficient production and/or testing outcomes. Indeed, you can find out more information about starting on the journey towards your own sustainable lean lab by downloading our special whitepaper here.

But what about the digital lean lab? The term “digital” is often co-opted to convey vague notions of efficiency and modernity. However, the process of digitalizing your lean lab involves more than simply moving from pen and paper to iPads! To achieve genuine “digital lean lab” status, you must update your existing way of working beyond the superficial.

One way to achieve this is by reducing the load placed on human planners by implementing end-to-end updates that integrate intelligent algorithms with established processes and allow the automatic calculation of strategy and optimal resource management and scheduling.

Early digitalization of lean labs

Lean principles for lab planning have historically been implemented in an analog fashion, often involving physical systems (daily huddles, planning boards) and manual processes (workload leveling via trains/rhythm wheels, role cards). Over time, such methods have, themselves, become more advanced as they try to keep up with the increasing complexity and quantity of operational data. Capturing and standardizing such data in a format that can readily be applied to manual planning methodologies became one of the most prominent early drivers of lab digitalization.

During those early days of digitalization, stakeholders were often skeptical about the ability of automated systems to replace their human-powered processes, opting instead to rely on in-house, manually-maintained spreadsheets as an adjunct to continued analog practices. An added benefit of increasingly harmonized lab data, however, is that it can also serve as inputs for more sophisticated technologies. With the emergence of advanced cloud-based digital scheduling products like Binocs, we are now witnessing a sea-change in industry perspectives.

Digital planning in lean labs

As the complexity of pharmaceutical molecules increases, so too do the associated manufacturing and quality processes; with increasing complexity, the various lab responsibilities become ever-more challenging. Now that sophisticated digital resource management products are more accessible, labs are starting to both embrace digitalization and reflect on its broader goals. As the push towards digitalization drives forward, it’s essential to realize that its true business value transcends simple savings in time and money – it should also prioritize making life easier for your most important assets: your human workforce.

Faced with this increasingly complex landscape, Astellas Pharma asked their key lab staff how digitalization might be employed to improve their work environment. For their QC Chemists, the most significant request was to have greater workload visibility and more transparency around lab scheduling, a daily process that was (at that point) manually controlled by a small number of managers. Conversely, for their Lab Managers, the request was not to have more information but rather to have better quality and greater consolidation of data sources to help guide their planning and decision-making processes.

These are precisely the insights that inspired the company to implement Binocs as a digital scheduling solution to replace the previous pen-and-paper approach in their QC Chemistry lab. Following a proof of concept investigation (ask us about this today!), we delivered the SaaS software with LIMS integration and comprehensive training within 16 weeks. As good change management prescribes, they nonetheless involved their end-users throughout the process. By maintaining this open communication, they ensured that the Binocs solution was consistent with the predefined expectations and desires around improvements.

Now a year post-Go-Live in the lab, users report that their needs have been met! This includes greater visibility on test demand and workload scheduling across the entire lab for weeks in advance; improved schedule adherence; improved workload leveling; training data consolidation that identifies gaps in team member competencies; and real-time, off-the-shelf KPIs that highlight business-critical data such as resource utilization and planning bottlenecks.

Navigating the Digital Lean Lab “revolution”

More and more labs are now waking up to the need for a comprehensive, digitalized approach to their lean lab practices and the central role that automated planning and scheduling plays in improving both working practices and business outcomes. However, a crucial (and often overlooked) aspect of successful digitalization and effective change management is stakeholder engagement.

The above description of Binocs implementation at Astellas Pharma represents an excellent real-world example of a best practice approach:

- Consult with your end-users to identify unmet needs

- In case of resistance to change, convince the non-believers by conducting a proof-of-value study to demonstrate the digitalization business value

- Select a professional digital solution based on the best fit for your requirements and that is configurable so it can grow with your digitalization journey

- Integration is key, so make sure the solution easily integrates with existing and future digital data sources

- Continue to engage your users throughout the implementation process and beyond

Why is stakeholder engagement so critical? Simply put, it’s because your digital lean lab is still populated by people, not machines! No matter how much you digitalize your laboratory practices, contemporary technology is still a long way from full automation. The most dynamic form of intelligence remains human, which is why Binocs scheduling is a co-bot: by automating highly complex calculations, the co-bot supplements rather than supplants the work of your skilled lab staff, allowing them to dedicate more time to the tasks that require that spark of human ingenuity. How can these complex calculations enhance your lab’s position in the emerging digital lean revolution?

Whether it is R&D, production, or quality control, your laboratory’s placement in the broader supply chain directly correlates with its operational excellence. Historically, lab resource planning has followed a “push” approach, wherein supply-side availability and the ability of decision-makers to forecast variability determines (and thus limits) product delivery to the customer. However, demand-driven supply chains can more optimally manage supply chain stability and efficiency. This is where a scheduling co-bot can really shine as it applies the business rules for the supply chain strategy, whether this is time-to-market for new products or efficiency-driven for the runner products or a mix of both!

With increasingly sophisticated algorithmic support, you can now react to true business priorities by pivoting away from cost- and service-focused supply chain management to material flow speed and real-time information visibility. Even in a QC context, where resource management is more reliant on standard lead times and exceptions, Binocs dynamically incorporates these factors into its agile planning processes. This allows scheduling and workload leveling to be re-optimized at the click of a button and can identify upstream and downstream bottlenecks via responsive dashboards (https://discover-binocs.com/binocs-performance-twin-the-dashboard-platform-for-qc-performance-kpis)

Looking ahead: from co-bots to lab autonomation

We have seen how digital resource management is a key enabler of today’s digital lean lab but what about the future?

At present, pharmaceutical production and QC remain a human-centric industry; as mentioned above, we are still some distance removed from a dramatic change to this paradigm. Indeed, as highlighted in our blog on the pitfalls of automation, it is possible to have too much of a good thing! Nevertheless, it would be naïve to think that the industry standard won’t focus on full automation in the lab of the future.

Pioneering Japanese industrial engineer Shigeo Shingo once identified 23 steps between completely manual manufacturing processes and full automation; however, he also suggested that 90% of the benefits of full automation can be achieved, instead, through autonomation.

The current, semi-automated Binocs system presents a human operator (e.g., a lab planner) with an operational suggestion for them to either approve or adjust manually before implementing. By contrast, autonomation is a proposed system of intelligent automation in which human intervention is required only when a problem is detected. As artificial intelligence becomes more advanced, it is expected that more and more lab processes will follow this model.

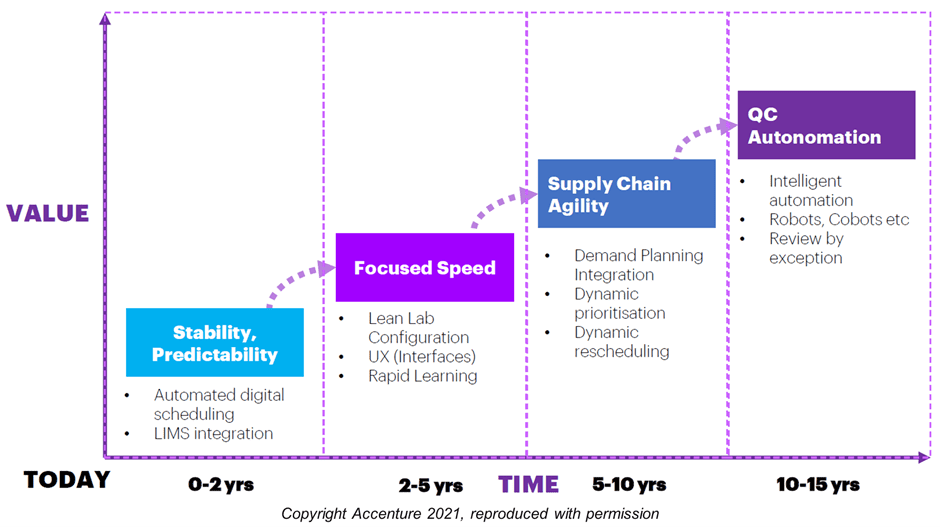

As you can see from the above diagram, digital scheduling is positioned as the first step in the journey towards full autonomy. Indeed, Binocs is already firmly established as the market leader in both co-bot planning and advanced interoperability with third-party data sources, such as LIMS systems. But we are also continuously evolving and adapting the system to new client requirements and broader trends in the lean lab ecosystem as we strive to pave the way for the next leap forward in the digital lean lab.

Interested in learning more? Why not book a demo today?

Adam Lester-George

Adam has two decades of experience working in clinical trials, biomedical research, public health, and health economics, with a particular interest in the intersection between technology and life sciences. For 7 years before joining Bluecrux in 2019, Adam was the director of healthcare innovation consultancy “LeLan” and brings a wide range of insights to his role as Content Specialist for Binocs.