4 ways equipment resource management optimizes asset utilization in QC labs

Equipment is expensive, so you need to ask yourself: are we using our equipment as efficiently as possible? Is it giving us the desired return on investment? Should we invest in new equipment or solve capacity bottlenecks by better utilizing the equipment we already have? In order to optimize instrument uptime and increase throughput, you need data as described in this blog article. That data can be used to learn from the past (backward-looking) and anticipate the future (forward-looking). A digital twin of your lab (like Binocs) not only captures historical equipment performance data but has forecasting capabilities to prevent equipment bottlenecks before they even occur. Let’s have a look at the four key domains where Binocs helps labs in optimizing asset utilization.

Minimize idle time through equipment reservation management

No matter what type of laboratory, the work is equipment-intensive (HPLC, Karl Fisher, Incubators, wave bags, different types of bioreactors…) and the planner needs to be 100% sure the right equipment will be available at the right moment to execute the work without interruption. Partially overlapping equipment bookings are one of the leading causes of equipment & analyst idle time.

With an equipment plan-board, Binocs gives immediate visual feedback if key equipment is available to confirm new requests (capable of promise). Based on that feedback, the planner can propose to change the start date or find other solutions – all optimizing the optimal usage of your equipment.

Optimize short term utilization through optimal campaigning

Many consultants identify optimal campaigning of samples as one of the key opportunities to optimize throughput in a lab context. The reason is simple: the more samples you process in one run, the lower the hands-on time and equipment lead time per sample. Or in other words: you process more samples (throughput) with the same capacity (optimizing utilization rates).

But as described in this blog article, doing this ‘on paper’ sounds easier than it is. To really bank on the opportunities campaigning presents and fully optimize asset utilization, you need a co-bot that can create campaigns automatically & intelligently.

In Binocs, his is what we call the campaign manager, based on rules business users can configure. The results we’ve seen are impressive: increases in throughput of +30% (increase in utilization) without it affecting the planning adherence (link to research done over summer).

Optimize equipment sharing by looking at the planning

Having a digital twin of your lab becomes even more interesting when you start working with forward-looking capabilities. A capacity report, like the example below, gives you an indication of all workload you expect to be delivered late in the next few months.

Once you have that high-level visibility, you can start zooming in on where the late workload is coming from. This allows you to, for example, generate insights on one team that expects to deliver specific samples late due to equipment bottlenecks, while another team expects certain equipment to have quite a bit of idle time.

Having this visibility then allows you to share equipment across teams to not only solve the bottleneck (increases planning adherence) but also minimize equipment idle time (optimizing asset utilization and throughput).

In Binocs, you can configure that solution, allowing you to share equipment across teams. Once configured, the scheduling algorithm will take this into account.

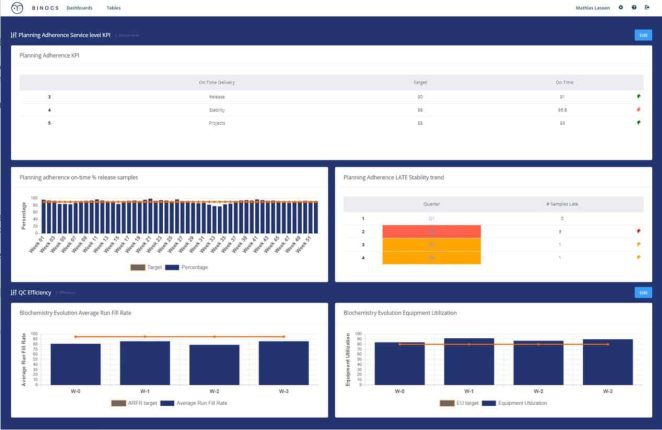

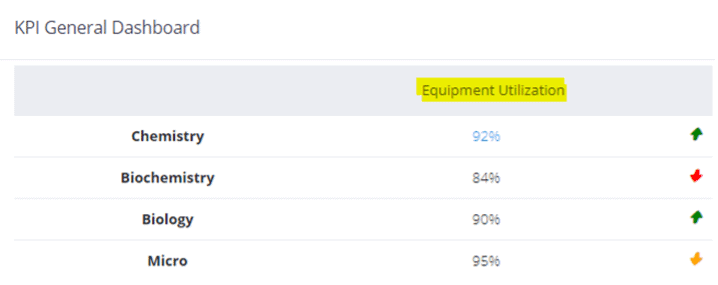

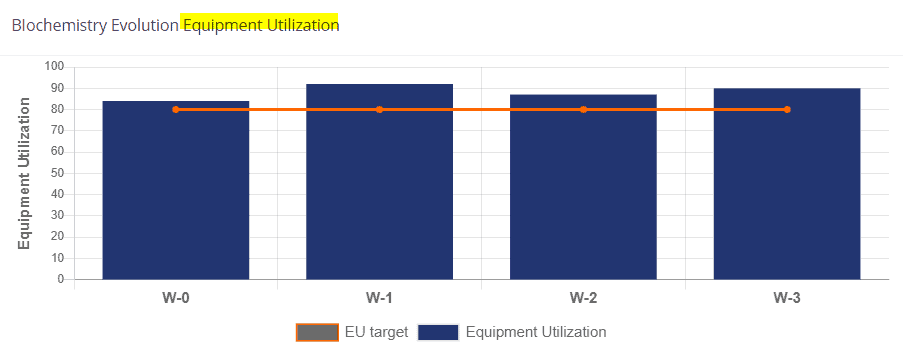

Tracking the results: visualize equipment utilization KPI and track downtime reasons.

If you can’t measure it, you can’t improve it. Binocs captures equipment performance data and makes it available to create all kinds of KPI reports. Two high-level screenshots of KPIs below:

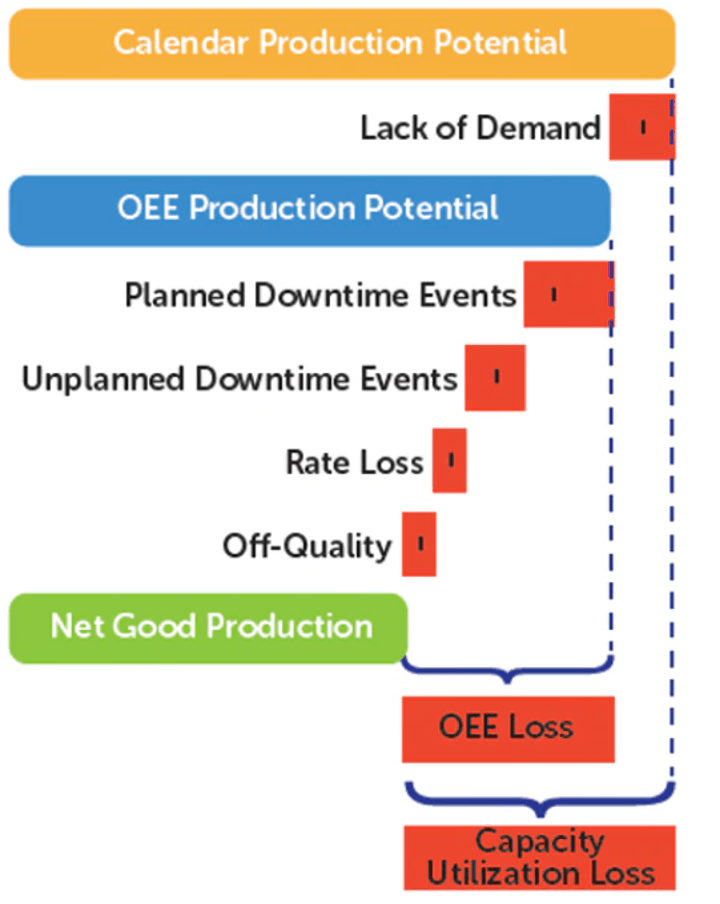

Due to the nature of the data that Binocs is capturing, you can then further zoom in on ‘why the utilization’ for team X was lower than the utilization of team Y. This is getting you pretty close to map your overall equipment efficiency, typically visualized as shown below:

We’re working on a blog series about how Binocs can help labs fully optimize asset utilization, so stay tuned for the next blog where we’ll showcase how Binocs can zoom in on ‘reasons why’!

-

Would you like your lab to be 100% automated? Not so fast! First, let’s take a closer look at lab automation and ask: how much is too much?Read more

-

A balanced scorecard for resource performance

Business context We are a department of about 450 people. 70% of our work are projects that can be sub-divided into 12 project types with a standardized template. We…Read more -

Exploring the value of lab KPIs: asset utilization metrics

Continuing our series of monthly blogs on the value of different lab KPIs, this post explores asset utilization metrics. In contrast with the previous posts that presented quantitative measures…Read more

Geert Vanhove

Geert has over 30 years of experience in supply chain and quality operations consulting. He began his career as a product manager for a MES/LIMS application at Compex (later acquired by Siemens). After co-founding Bluecrux, he dedicated his expertise to designing the first iteration of Binocs which, under his stewardship, has since gone on to become the market leading planning and scheduling solution for labs.