Supply chain data harmonization: The role of AI & ML

The importance of artificial intelligence (AI) and machine learning (ML) in supply chain data harmonization is in helping you to rise to the challenge of creating end-to-end visibility. Let me explain.

Linking the ‘Islands of Information’

There are multiple factors that complicate end-to-end supply chain visibility. However, in most cases, it starts with legacy. It’s typically not possible to start out with a blank slate. And, as research analysts tell me, the average organization has three to four ERP systems. Because of the way these organizations grew historically, they have created islands of information. Each planning system has its own data, based upon which it offers solutions.

The initial challenge is to gather all this data, which is scattered across platforms, and create a harmonized representation of the supply chain. Here is where AI and ML kick in using fuzzy matching algorithms to match and structure records across the platform that are not necessarily referred to in the same manner.

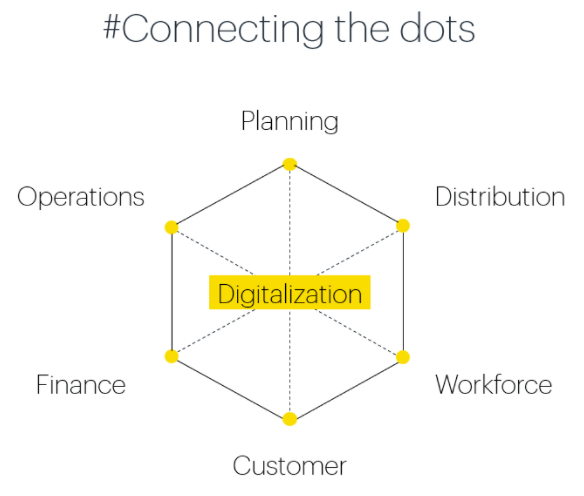

The advantage of having access to smart algorithms is that the interconnectivity is being mapped out automatically. Using the aforementioned probabilistic (fuzzy) matching to link flows across the supply chain, we can overcome the sole reliance on the accuracy of the master data. This way the AI and ML connect the dots throughout the supply chain, linking contract manufacturers, suppliers, customers—creating the end-to-end visibility and supply chain data harmonization you need.

Advantages of automation

This automation has many advantages. It’s more accurate, it’s dynamic and you have the ability to analyze how your supply chain variables change over time. This restructuring of data and tracking of variables can also be used to feed more accurate information back into your ERP systems. On top of being able to “keep your finger on the pulse of your supply chain” at all times, you have access to clever analytics that allow you to simulate a multitude of situations.

By having continuous access to the latest accurate information based on the demonstrated performance, you have the capability to become more resilient, allowing for a faster and more accurate response to change. How we react to change does not only determine if we survive but also whether we can thrive.

By implementing AI and ML into your supply chain, you can overcome the sole reliance upon the accuracy of the master data and create connected end-to-end visibility based on demonstrated performance.

Read on below to discover more about data mining with a digital supply chain twin: