How a digital supply chain twin can enable your multi-year SAP S/4HANA implementation

Companies around the globe have already begun—or will soon start—their SAP S/4HANA transformation journeys, for which end-to-end flows will be among the keys to their success. If you haven’t yet begun your S/4HANA implementation project, a digital supply chain twin can make it easier. If you’ve already started, it can help, too. These journeys can seem long and overwhelming, but I can assure you that with a digital supply chain twin, they don’t have to be. Technology can accelerate the process, empowering you and your supply chain to work smarter, not harder.

In a rush? Here are the 3 key takeaways:

- → A digital supply chain twin supports AS IS analysis, efficiently visualizing end-to-end product flows.

- →It provides more accurate information about master data that reflects real performance.

- →A digital twin decreases the workload and/or time for a given task during the S/4Hana implementation process while boosting the quality of the work.

- →With a digital twin, there will be fewer extrapolations and assumptions.

- →Collecting and analyzing AS IS flows can be sped up, by up to 95%.

Supporting AS IS analysis

A digital supply chain twin like Axon can quickly visualize all your end-to-end product flows, which are based on transactional data and linked through our algorithms. Supporting all AS IS—as well as TO BE workshops—it can even visualize the exceptional flows that are not always documented.

The tool can also be used by different S/4HANA streams, including logistics, planning, finance and quality streams:

- Planning & Logistics: Flow and frequency visibility is imperative in S/4HANA implementation.

- Finance: You need visibility on financial flows (involving virtual plants) and the physical flows (excluding virtual plants).

- Quality: Visibility on process orders, batches and batch genealogy enables useful input for production and quality teams.

→ What else can the digital supply chain twin do to support AS IS analysis? It can aid development by providing unit test data. It can also improve user accepted testing (UAT) by providing input for flows to test and to be able to compare with previous AS IS analysis.

Only the best data

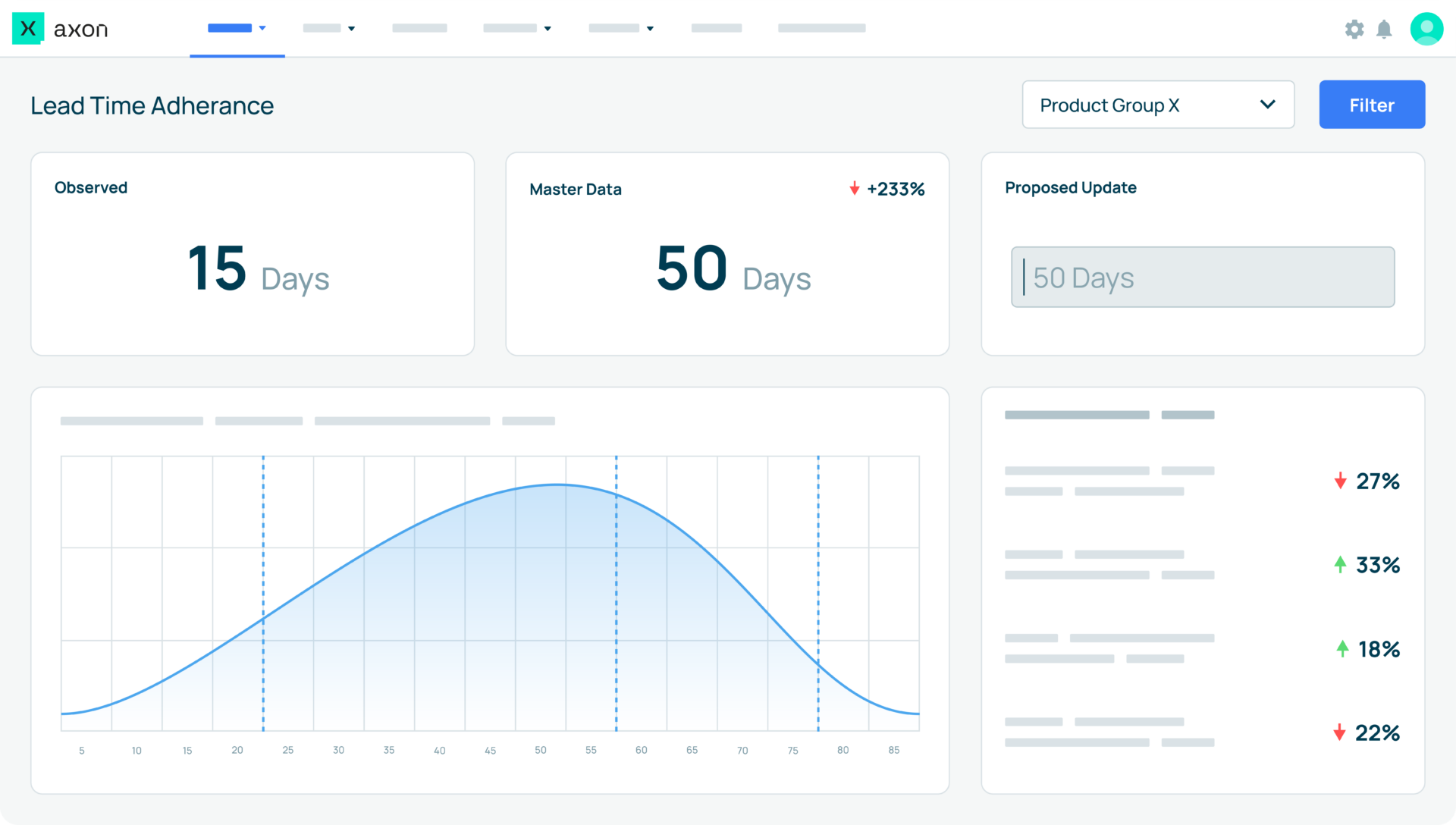

While supporting AS IS analysis, a digital supply chain twin can deliver better information about data. It can help by calculating what the value of the planning master data should be, based on your demonstrated performance.

SAP Integrated Business Planning (SAP IBP) is often part of an S/4HANA program. Some data sits in S/4, including average inspection duration (AID), planned delivery time (PDT), in-house production time, etc. It is available from a legacy system (ECC), but it is still best practice to double-check if values are accurate when launching a new system, as opposed to relying on business-as-usual parameters.

Perfecting product flows

A digital supply chain twin can aid in the analysis and optimization of product flows. Instead of collecting data yourself from different SAP systems, you have a tool that enables you to see the flows on the fly in a visual manner. In implementing your S/4HANA supply chain processes, a digital supply chain twin will make certain tasks a lot easier, decreasing the workload and/or time for that task (decrease full-time equivalent (FTE)) or increasing the quality of the work done.

→ A digital supply chain twin enables you to efficiently investigate more flows in detail, leading to fewer extrapolations and assumptions.

Simplifying your S/4HANA implementation

What is fundamental to completing a qualitative S/4HANA implementation? End-to-end flows and accurate data. In theory, you can dig up flows and data manually. In practice, however, this doesn’t work. It takes too much time, requires in-depth knowledge from a very broad and scattered group of people and is incredibly challenging to keep up to date. Through Axon, you have full visibility on ALL flows, ALL data and on ALL levels of granularity at ALL times. AND, it is there to keep on supporting you after your S/4HANA project is completed—what more could you want?