What is a Digital Twin?

You may have heard these terms before, but precisely what is a digital twin? Axon’s digital supply chain twin is more than just a marketing term, it’s the next step in fine-tuning your organization’s supply chain.

The term has become fairly common, though there is still a lot of confusion about its meaning. It is essentially a virtual representation of a physical object or process that captures both physical and behavioral characteristics. But the reality is that the definition has changed over time and that digital twins are being developed for different purposes.

→ While each purpose is valid and valuable in and of itself, there are common characteristics to be discovered below.

Origins of Digital Twin

The origins of the term digital twin is in the equipment design space, usually for very large military construction projects. You can imagine how many documents are required to capture the design of an aircraft carrier. The maintenance of these documents, in paper form, was a colossal effort, leading to errors, which in turn led to huge costs and periods of inoperability of the assets.

This shift from capturing the design in digital format to capturing performance is very important in the use of digital twins. The digital capture of the dynamic performance characteristics was a huge leap forward because this telemetry could be analyzed in detail after the fact.

Digital Simulations & Supply Chains

All the telemetry that was captured facilitated the development of detailed digital simulation models. While simulation had been used to some extent during the design phase, the collection of real performance telemetry represented an incredible increase in the fidelity of the digital twin simulations.

As you can imagine, it is a lot less expensive to test a design using digital simulation than a physical simulation, such as a crash test. However, the initial digital simulations were limited by computing power and software to component analysis, usually of the physical characteristics rather than system analysis, which is more about how the components interact.

Once we get to complex systems made up of many components, such as supply chains, we get into the need to design and capture policies—operating modes, inventory levels, preferred suppliers, market segmentation, revenue targets, etc. These policies are just as important to the achievement of operational goals as is the physical nature of the supply chain.

The important point about this is that the supply chain design, specifically the policies, needs to be under constant review based upon the actual performance. The physical supply chain is a lot more difficult to change in a short period of time. However, the internal policies can be changed in seconds, while external policies, such as customer delivery lead time or supplier delivery lead time, require more time. And some policies require the approval of external bodies, such as the EDA or FDA approval in pharmaceutical manufacturing and distribution.

Simulation is of huge value in evaluating the impact of policies. Of course, there is always the question of the fidelity of the simulation model. The fidelity can be split into the “physics” of the model as well as the input values. In other words: are the policies and operational capabilities of the supply chain represented correctly from a mathematical perspective, and do the input parameter values represent realistic values?

So what is it exactly?

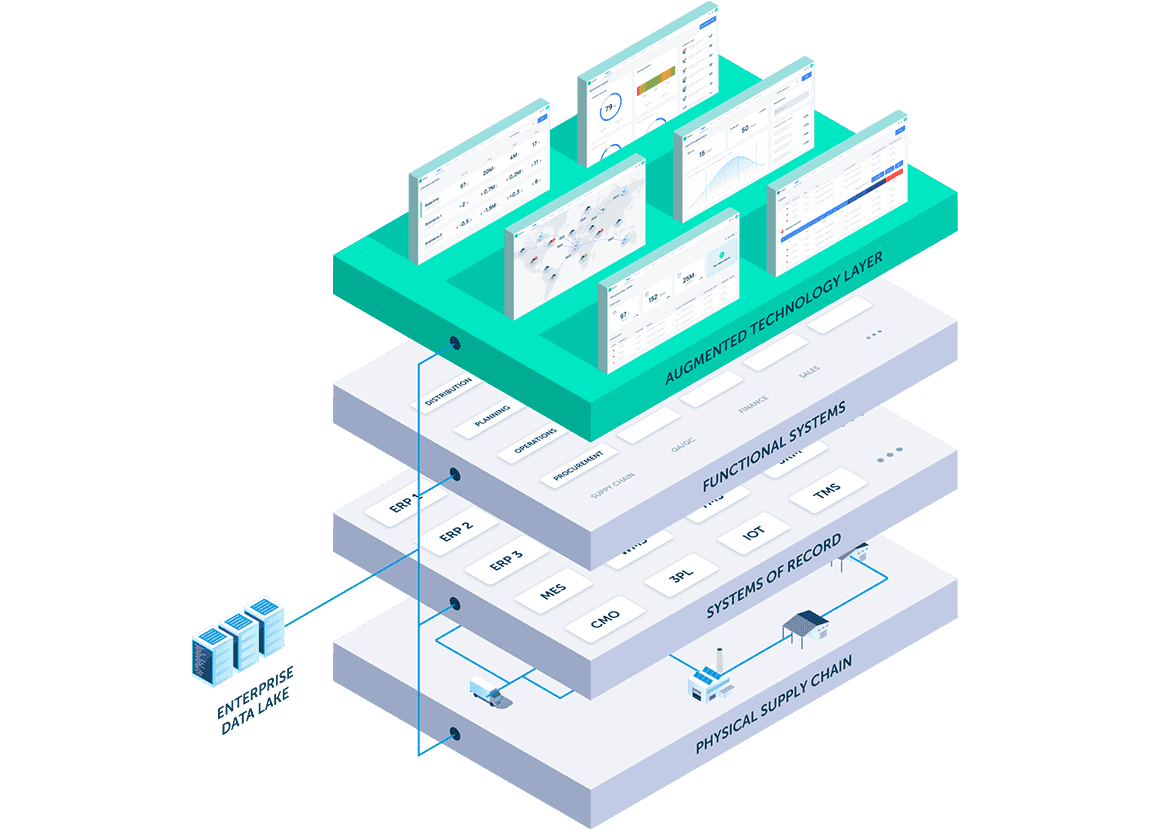

According to Gartner, a digital supply chain twin is ‘’a digital representation of the end-to-end physical supply chain that can be used to drive understanding and make decisions.’’ The goal is to have one end-to-end supply chain data model, from sourcing through to delivery.

→ It is built from granular data to form a dynamic, synchronized, real-time and time-phased representation of the various associations between the data objects and entities that ultimately describe and make up how the physical supply chain operates.

What are you waiting for?

By capturing your demonstrated performance and incorporating end-to-end inherent variability, not only can you drive understanding in order to facilitate design improvements, policy improvements, process improvements and conformance and compliance, you can also enable better decision-making through early alerting when significant changes might be occurring and predicting the consequences of the changes—and by estimating the likelihood that a plan will produce the intended results.

Explore How a Digital Supply Chain Twin Enhances Global Decision-Making. Register now to watch our webinar!

→ As Gartner states, a digital supply chain twin will allow you to “move from unknown uncertainty to known variability,” and to include that variability in your decision-making through probabilistic planning.

Discover what our digital twin Axon can do for you.

Request a Demo